Did you know that electrical machines are crucial not only in power generation but also in power consumption?

Just think about all the things in our daily lives that rely on electrical machines, from power stations and factories to farms, railways, automobiles, and even aeroplanes. Without these essential machines, modern life as we know it simply wouldn’t exist.

In fact, the invention of electrical machines was a major driving force behind the Industrial Revolution.

Generators, motors, and power converters have all played a significant role in enhancing the productivity of industrial and commercial sectors. Electrical machines are so much engraved in various applications that they are never going to cease to exist.

That’s why today’s blog post is all about electrical machines. We’ll cover everything you need to know about them, from their features and types to their essential role in modern society. So, let’s dive in and learn more!

Also Read: Electrical Transformers | A Deep Dive into its Mechanics

Why do we need electrical machines?

Have you ever wondered how you’re able to use energy from different sources for different purposes?

Energy exists in different forms, and you can’t always use them directly for what we need.

This is where electrical machines come into the picture. They help you convert energy from one form to another. Either from mechanical energy to electrical energy or vice-versa.

For example, a generator in a hydroelectric power plant converts mechanical energy to electrical energy. This electrical energy is transferred over long distances to our homes and businesses.

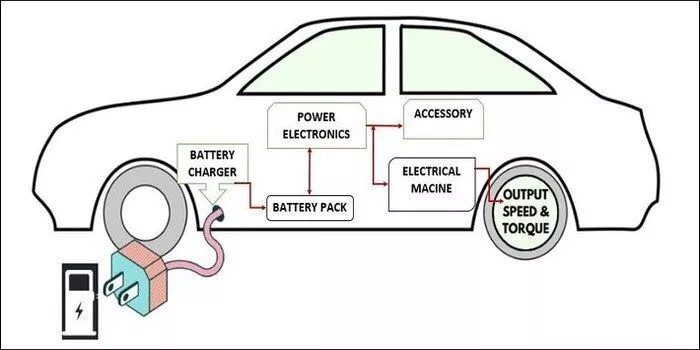

Similarly, in an electric vehicle, a motor is used to convert electrical energy stored in the battery into mechanical energy to power the wheels. Further, the same motor acts as a generator and converts the kinetic energy of the vehicle into electrical energy that can be stored in the battery.

Overall, electrical machines are crucial because they help us efficiently convert and use different forms of energy for various applications.

Without them, it would be difficult to generate, transmit, and use electrical energy for the many things we rely on every day.

To put it simply, electrical machines play a key role in making sure that you have access to energy in the right form and at the right place where you need it.

Also Read: AC Motor | Construction, Types, Advantages & Applications

What is electrical machine?

When you read a regular book on electrical machines, it usually talks about each machine separately and explains its operation one at a time.

This makes you think that each machine is entirely unique and operates based on different principles. But that’s not entirely true.

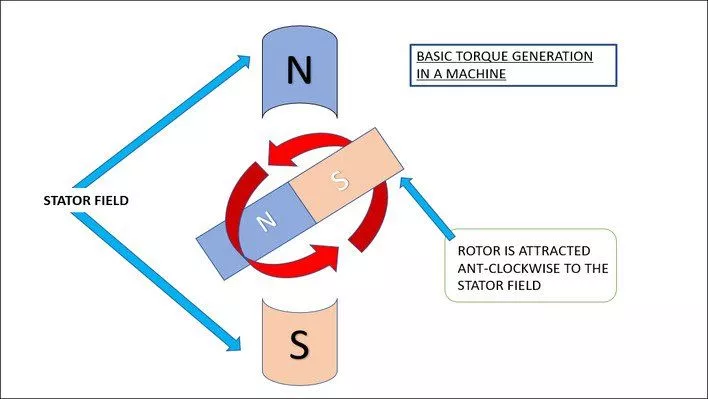

If you take a closer look at all the rotating electrical machines, you’ll notice that each one has two magnetic fields. And the reason these machines work is that these magnetic fields are always trying to align with each other.

So, in a way, they’re all related to each other and not as different as you might think.

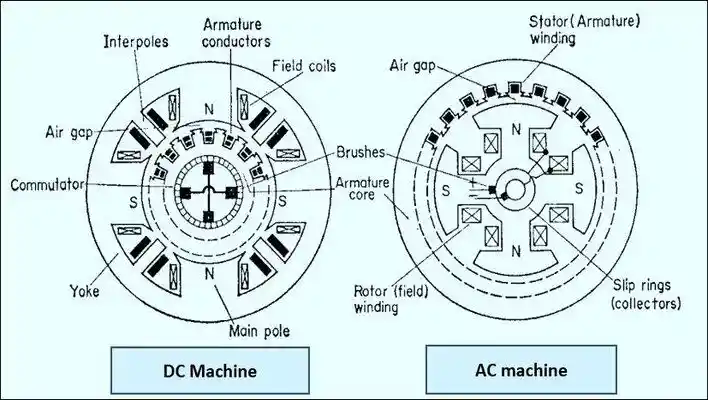

Electrical machines are divided into four basic types of machines. Out of the four the first three are rotating machines while the last is a static machine. They are,

- DC machine

- Poly-phase synchronous machine (AC)

- Poly-phase induction machine (AC)

- Transformer.

Electrical machines can be rotating machines or stationary/static machines. They are important because they help us convert and utilize energy in the most efficient and effective way possible.

Basic constructional features of Electrical machines

When machines are made, there are usually three materials that are used the most.

First, there’s steel which is used to conduct magnetic flux.

Then there’s copper or sometimes aluminum used to conduct electric current.

And finally, Insulation is used to prevent the voltage induced in conductors from escaping and confine currents to them.

As electrical machines are made of current circuits made of insulated conductors and magnetic circuits made of steel (ferromagnetic) materials.

These circuits work together with a magnetic field to create mechanical energy, which means the machine can do some physical work.

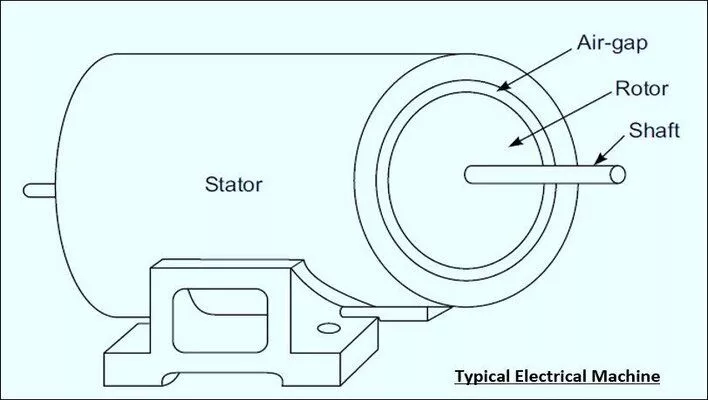

Conductors and ferromagnetic elements belong either to the moving part of the machine (rotor) or to the stationary part (stator).

The electricity flowing through the insulated wires in the machine (called windings) interacts with the magnetic field to produce forces that make the rotor move.

When the rotor moves, it causes changes in the magnetic field. These changes create a type of electricity called electromotive force, which is used to generate electrical energy.

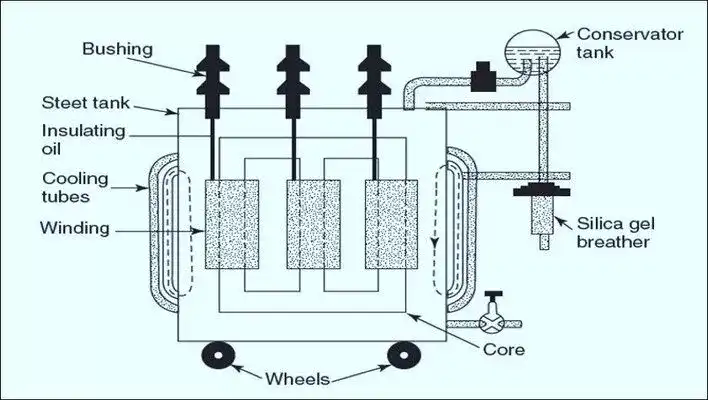

Unlike rotating machines, power transformers do not have moving parts.

Instead, they operate through electromagnetic coupling between the primary and secondary windings that surround the same magnetic circuit.

The coils and core of a power transformer remain stationary relative to each other, and the periodic variations in the magnetic field required to induce electromotive force (emf) in the coils are produced through electrical means rather than mechanical.

Also Read: Explore the Diverse World of DC Motors

Types Of electrical machines

Rotating machines

A rotating machine is a type of electrical machine that transforms electrical energy into mechanical energy or vice versa by using rotating parts.

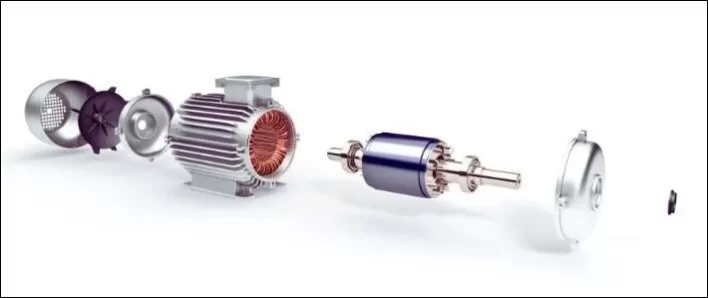

These electrical machines usually have two primary components – a rotor and a stator. The rotor rotates around the stationary stator, producing an electromagnetic field.

This electromagnetic field interacts with the magnetic field of the stator, which results in the conversion of energy from one form to another.

The most common types of rotating machines are motors and generators.

Motors convert electrical energy into mechanical energy by using the interaction between the magnetic fields of the stator (the stationary part) and the rotor (the rotating part) to create a rotational force.

This rotational force is used to drive a load, such as a fan, pump, or conveyor belt.

Generators, on the other hand, convert mechanical energy into electrical energy by using the opposite principle.

A generator’s rotor is turned by a prime mover, such as a steam turbine or water turbine, which creates a rotating magnetic field in the stator coils. This field induces an electrical voltage and current in the coils, which can then be used to power electrical devices.

In addition, there are other types of rotating machines like synchronous machines that work at a constant speed and induction machines that are mainly used for low-speed applications.

Synchronous machines are very similar to generators, but they are operated at a fixed speed, whereas induction machines are similar to motors but are designed for specific applications with lower speeds.

In summary, rotating machines are devices that convert electrical energy into mechanical energy or vice versa. They include motors, generators, synchronous machines, and induction machines.

Static Machines

Static electrical machines are those machines that do not have moving parts, unlike rotating machines. For example devices like transformers that transform current and voltage from one value to another value of voltage and current via electromagnetic conversion.

Unlike rotating machines, static machines do not have any mechanical parts that move, which makes them less prone to wear and tear and often more reliable.

Electromagnetic electrical machines are the primary type of machines used, but there are certain special applications where electrostatic machines are utilized for the conversion of energy based on electrostatic induction, utilizing a capacitor with movable plates and periodic changes in its electric field.

Nonetheless, due to their inferiority in size, weight, and cost when compared to electromagnetic machines, electrostatic machines are not employed in commercial or industrial settings.

Also Read: Synchronous Electric Generator | Principles & Working

Basic constructional features of DC Electrical machines

Here’s a breakdown of the different components that make up a DC electrical machines. These features are common to various types of DC machines, including DC motors and DC generators. The specific design and arrangement of these components may vary based on the intended application and performance requirements of the machine.

Rotor – This part of the machine is responsible for providing rotational motion. In DC generators and motors, the rotor carries the armature windings.

In a generator, external forces like steam turbines are needed to rotate the rotor and induce voltage and current in the armature, creating electrical energy.

In a motor, the rotor turns the equipment that it’s coupled to it, converting electrical energy into mechanical energy in the form of torque.

Stator – It is a part of a motor or generator that is stationary. The stator, which is a hollow cylinder, carries the field windings and together with the rotor form the magnetic circuit or core of the machine.

Armature winding – This continuous winding is made up of coils that have no beginning or end, and it’s mounted on the rotor. The armature winding rotates in the magnetic field that’s set up at the stationary winding, converting energy in the DC machine.

External mechanical forces such as steam turbines are required to spin the armature winding in DC generators. The spinning causes inducement of voltage and current in the armature. Thus armature creates electrical energy from mechanical energy.

In DC motors an external electrical source provides power to the armature which enables the armature to convert electrical energy to mechanical energy in the form of torque.

Field winding – This exciting system is located on the stator and can be made up of either electrical winding or a permanent magnet. The magnetic field provided by the field windings produces voltage or torque in the DC machine.

Commutator – The commutator is responsible for terminating and interlinking the loops of the armature windings. It’s made up of bars and segments that are insulated from each other and rotates with the rotor. The commutator rectifies the induced voltage and current in the armature, which are both AC.

Brushes – Brushes provide contact of the generated voltage to an external circuit. They’re made of conducting carbon graphite and are in constant contact with the commutator thanks to a spring mechanism.

Poles – The field winding is placed in poles, the number of which is determined by the voltage and current ratings of the machine.

Insulation – Insulating materials are used to prevent electrical leakage and ensure the safety and reliability of the machine.

Basic constructional features of AC Electrical machines

The basic construction of AC electrical machines such as generators and motors are the same.

Stator Core – The stator is the stationary part of the AC machine. In most AC machines, the stator contains a core made of laminated iron or other magnetic materials.

There are slots on its inner periphery. The three phase winding are placed in the slots which serve as armature winding. The stator is wound up for three phase supply and its connections are brought in the terminal box. Alternator and motor have identical stator windings.

Rotor – For AC machines rotors can be wound type or squirrel cage type. The rotor of the squirrel cage motor is cylindrical and is built up with laminations having slots on its outer surface. Solid copper conductors are placed in these slots and are short circuited at the ends of the rotor by brazing or soldering.

Bearings – Bearings are used to support the rotor and allow it to rotate smoothly within the stator. Bearings reduce friction and wear, contributing to the efficiency and longevity of the machine.

These constructional features are common among different categories of AC machines, which include induction motors, synchronous motors, and AC generators. The precise configuration and layout of these components can vary depending on the intended application and the performance criteria of the machine.

Also Read: In-Depth Guide to Variable Frequency Drives (VFD)

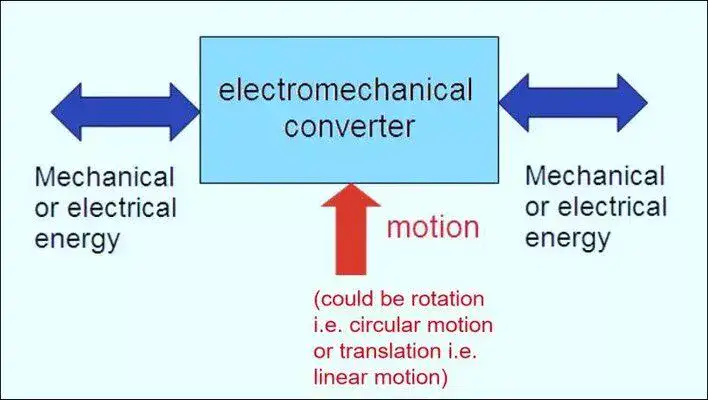

What is the principle of electromechanical conversion?

Electromechanical conversion is a technical term used for the process of converting electrical energy into mechanical energy, or vice versa.

It is accomplished through electrical machines and devices designed to transform one form of energy into another.

Basically, in an electromechanical system, energy is converted through the interaction of electrical and magnetic fields.

When an electric current flows through a conductor, it creates a magnetic field around the conductor. And when a magnetic field interacts with a conductor, it induces an electrical current in the conductor.

This principle is used to design electrical machines that can convert energy between electrical and mechanical forms.

For example in motors the electrical energy is converted into mechanical energy by using the interaction between magnetic fields and electrical current.

The motor has a rotor and a stator, with the rotor rotating inside the stator.

The stator contains a series of electromagnets that produce a magnetic field, while the rotor has a set of conductors that carry an electrical current.

The interaction between the magnetic field and the electrical current causes the rotor to rotate and generate mechanical energy.

Another instance of electromechanical conversion is the generator, which changes mechanical energy into electrical energy. It works by utilizing the interaction between a magnetic field and a conductor.

The generator is made a rotor and a stator, with the rotor spinning inside the stator.

The rotor has a set of conductors that move through the magnetic field created by the stator, producing an electrical current in the conductors.

This electric current is then sent to an external circuit, generating electrical energy.

Electromechanical conversion is used in a wide range of applications, such as power generation and transmission, electric vehicles, robotics, etc.

For example, steam turbines use this conversion to generate power by converting thermal energy into mechanical energy to drive generators.

And electric vehicles use electric motors to convert the electrical energy stored in batteries into mechanical energy to power the vehicle.

In short, electromechanical conversion is a crucial process that has transformed the way we generate, transmit, and use energy in modern civilization.

Basic laws determining operation of electrical machines

The basic laws of physics determining electromechanical energy conversion in electrical machines with magnetic coupling field are:

- Faraday’s law of electromagnetic induction which states the correlation between varying magnetic flux and induced electromotive force.

- Ampere’s law which explains the magnetic field of conductors carrying electrical current.

- Lorentz law which determines the force acting on moving charges in magnetic and electrical fields.

- Kirchhoff laws state the relationship between voltages and currents in current circuits and also between fluxes and magneto-motive forces in magnetic circuits.

- Ohm’s law

- Biot-Savart’ s law of force on a conductor in a magnetic field

- Watt’s determination of the relation between force, work, time and power

Is electrical transformer an electromechanical device?

Transformers and solid-state converters are not considered as electromechanical energy conversion devices because they do not involve any mechanical motion in the conversion process.

Instead, they convert one form of electrical energy into another form with different parameters, such as voltage, current, frequency, number of phases, or the conversion of DC into AC current, using the principles of electromagnetism and electronics.

Hence, they are classified as electrical energy conversion devices or power electronic devices, but not as electromechanical devices.

Also Read: Decoding DOL Motor Starter | A Complete Guide

Summary

- An rotating machine can either be operated as a motor or a generator.

- Every rotating machine consists of two main parts, namely stator and rotor.

- Stator construction is in the form of a hollow cylinder with the inner surface either having slots in which windings are placed, or alternatively having projected poles with windings placed around them.

- Rotor construction is in the form of either a solid cylinder having slots on its outer surface in which windings are placed or a rotor cylinder having projected poles with windings placed around them.

- Windings of both stator and rotor carry current which produce a common magnetic flux in the space called the air-gap between the stator and the rotor.

- Machines has suitable devices such as fixed terminals, slip-rings, commutators, brushes, etc., for leading current in and out of its two main parts.

- Every machine has its supporting frame, enclosure, bearings and cooling arrangements.

- Transformers and solid-state converters do not belong to the group of electromechanical energy conversion devices because they only convert one kind of electrical energy into another kind of electrical energy with different parameters.