A synchronous electric generator stands as a cornerstone of power generation. Understanding its principles and working mechanism is essential for harnessing electrical energy efficiently. This post delves into the details of synchronous electric generators, revealing the core principles that drive their operation and shedding light on their all-important role in power systems.

What is a Synchronous Electric Generator?

IEC 60034-3:2020 defines Synchronous Generator as,

“a large synchronous machine driven by steam or gas turbines which converts mechanical energy into electrical energy and supplies it to an electrical grid.”

Now, IEC emphasizes that “synchronous generator” is synonymous with “synchronous machine.”, so lets understand what synchronous machine is,

A synchronous machine is an electrical machine that converts mechanical energy into electrical energy (generation) or vice versa (motor operation).

The key characteristic of a synchronous machine is that its rotor (or field winding) rotates at the same speed as the stator’s magnetic field. This synchronous motion is maintained through synchronization with the frequency of the electrical system to which it is connected.

Also Read: AC Motor | Construction, Types, Advantages & Applications

Further, synchronous generator is also called Alternator or AC generator because of the following reasons,

Alternator: The term "alternator" is often used interchangeably with "synchronous generator." Both terms refer to a machine that generates AC electricity through the synchronization of the rotor's rotation with the stator's magnetic field.

AC Generator: An AC generator is a device that converts mechanical energy into electrical energy, producing alternating current as its output. In a synchronous generator, the rotating motion of the rotor (driven by a prime mover such as a steam or gas turbine) induces an alternating voltage in the stator windings. This alternating voltage results in an AC output.

Synchronous Electric Generator Construction

In a synchronous electric generator, a three-phase power supply is taken from the stator, and the rotor winding is energized with direct current (DC). The rotor receives mechanical power from a prime mover.

Stator Core

The stationary component of the machine is composed of highly permeable thin steel sheet laminations featuring inner periphery slots. The stator accommodates the three-phase winding, functioning as the armature winding.

Stator Windings

Synchronous generators employ stators wound with three independent windings, designed to generate three-phase power. Typically, high-conductivity copper is used as the material for stator windings.

Although the three stator windings share a similar shape, they are positioned with a 120° electrical displacement from each other, ensuring induced electromotive forces are precisely 120° out of phase.

These three-phase windings can be connected in either star or delta configuration. In a star connection, the neutral point is accessible for proper grounding.

Rotor

Rotor carries field windings which are supplied with direct current through two slip rings by a DC source.

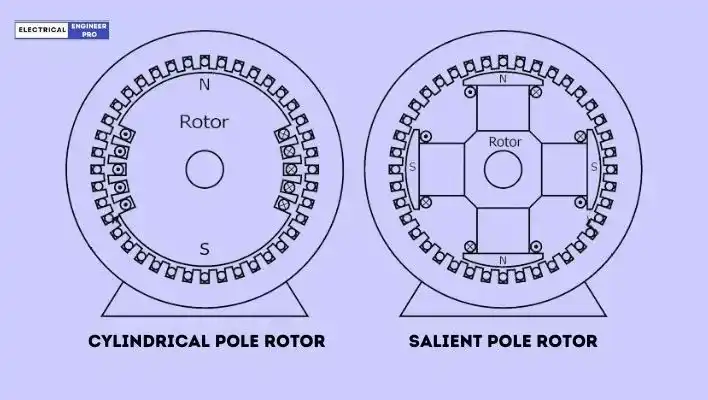

Depending upon the type of rotor, synchronous machines can be of two types,

- Non-salient pole or cylindrical rotor machine

- Salient-pole machine.

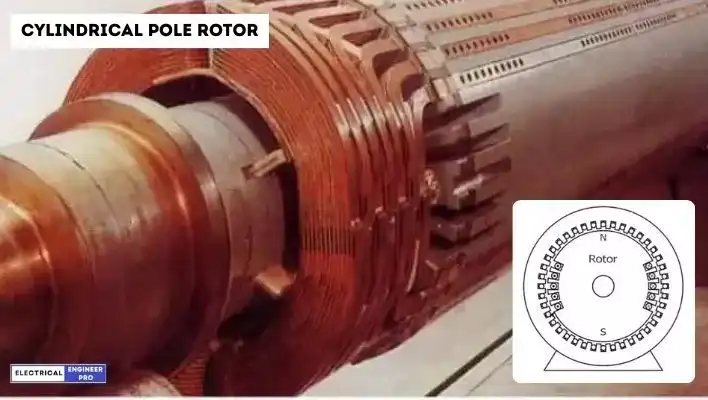

Non-salient pole or cylindrical rotor machine

- A cylindrical rotor, also known as a non-salient type rotor is made from a smooth solid forged steel cylinder with slots designed to house field coils.

- This rotor type finds application in high-speed alternators with a reduced number of poles.

- The rotor is constructed from solid steel forging, utilizing materials such as chromium nickel-steel or chrome-nickel molybdenum steel.

- Radial slots in the forging accommodate the field copper windings, arranged in striped form.

- Typically, two-thirds of the rotor features slots for the field winding, while the remaining one-third remains slot-less, forming the pole faces.

Salient-pole machine

- In a salient-pole-type machine, the rotor has a large number of poles projecting out from the rotor surface.

- These poles are bolted to a heavy magnetic rotor core of cast iron or CRGO steel of good magnetic quality.

- The field pole windings are connected in series, so that when the DC exciter energizes the field winding, adjacent poles get opposite polarities.

- The salient-type rotors are suitable for low and medium-speed alternators.

- In this type, at high speeds, there is excessive windage loss and more noise.

- Also they do not have adequate mechanical strength to run at high speeds. They require damper windings on the rotor to damp the rotor oscillations.

Frame

The frame serves as the protective enclosure for the entire machine, typically constructed from cast iron or steel to which the stator core is attached. Its design focuses on offering mechanical support to the generator rather than carrying the flux.

Also Read: Electrical Transformers | A Deep Dive into its Mechanics

Synchronous Electric Generator Operating Principles

The working principle of a synchronous electric generator involves the conversion of mechanical energy into electrical energy through the interaction of a rotating magnetic field and stationary conductors. Let’s break down the key steps in the working principle with an illustration:

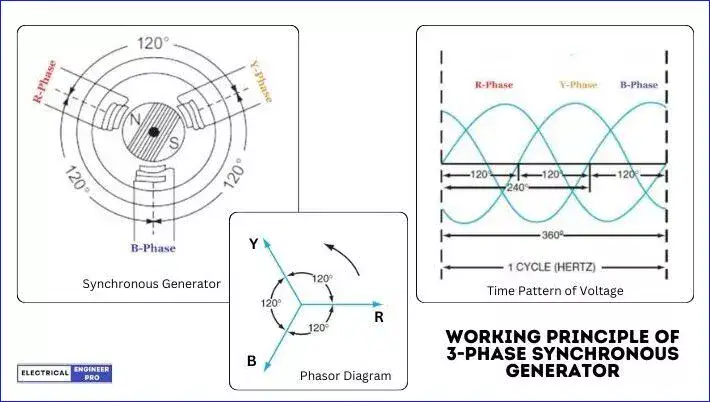

- Rotor and Stator Configuration: The synchronous electric generator consists of two main parts: the rotor and the stator. The rotor is the rotating component and typically includes a DC field winding. It may have pairs of poles depending on the design (2-pole, 4-pole, 6-pole, etc.). The stator is the stationary part with three-phase windings (as shown in figure R, Y, and B) placed in slots around its circumference.

- DC Excitation: The rotor is connected to a DC power source, known as the exciter, which supplies direct current to the rotor field winding. This creates a magnetic field around the rotor.

- Rotor Rotation: A prime mover, such as a steam turbine or gas engine, drives the rotor, causing it to rotate.

- Creation of Rotating Magnetic Field: As the rotor rotates, the DC field winding generates a magnetic field around the rotor. The rotor’s design ensures the formation of pairs of magnetic poles that move with the rotor.

- Interaction with Stator Windings: The rotating magnetic field produced by the rotor passes over the stationary stator windings. The three-phase windings (R, Y, and B as shown in figure) are positioned 120 degrees apart from each other.

- Induction of Voltage: The movement of the rotating magnetic field across the stator windings induces a voltage in each winding. The induced voltages in the three windings are sinusoidal and are displaced by 120 degrees in time.

- AC Output: The three-phase AC voltages generated in the stator windings are then combined to produce a three-phase alternating current. This AC output is suitable for distribution in power systems and can be connected to the electrical grid.

- Synchronization: Synchronous electric generators are designed to operate in synchronization with the frequency of the electrical system to which they are connected. The speed of the generator is adjusted to match the system frequency, ensuring stable and reliable power generation.

In summary, the working principle of a synchronous generator involves the generation of a rotating magnetic field by the rotor, which induces three-phase AC voltages in the stator windings. This AC output is then used for electrical power distribution.

Parallel Operations of Synchronous Electric Generators

Why Electric Generators are connected in parallel?

Electric Generators are connected in parallel to address various challenges that may arise when a single synchronous electric generator is tasked with supplying power to a load. Several situations can lead to disruptions or inefficiencies, prompting the need for parallel operation:

- Increased Load Demand:

- Challenge: When a generator is delivering its full load and there is a requirement to supply a larger load.

- Solution: Connecting multiple generators in parallel allows them to collectively meet the increased load demand efficiently.

- Generator Fault or Maintenance:

- Challenge: If a fault develops in the generator supplying the load, or if it needs to be shut down for maintenance purposes, there is a discontinuity of power to the load.

- Solution: Parallel operation ensures continuity of service by allowing other generators to seamlessly take over the load in case of a fault or during maintenance.

- Load Fluctuations:

- Challenge: The load on a generator may fluctuate, reducing its efficiency when operating below full load.

- Solution: Parallel operation enables the sharing of load among generators, allowing them to operate more efficiently across a range of load conditions.

By connecting generators in parallel, several advantages are realized:

- Meeting Additional Load Demand: Multiple generators working in parallel can collectively meet increased load demands, ensuring that power requirements are consistently fulfilled.

- Continuity of Service: In the event of a fault or maintenance on one generator, others in parallel can seamlessly take over, maintaining uninterrupted power supply to the load.

- Improved Efficiency: Generators operating in parallel can supply power to the load at higher efficiency levels, especially when the load is not at its maximum value.

The fundamental principle behind parallel operation is to ensure that electric generators collectively meet the load without any flow of current or power between the generators themselves. When connected in parallel, the generators exhibit voltage phase opposition within their local circuits but maintain phase agreement with respect to the external circuit. This configuration ensures a smooth transition of power delivery to the load when the generators are in operation.

What does the term “Synchronization of Generators” mean?

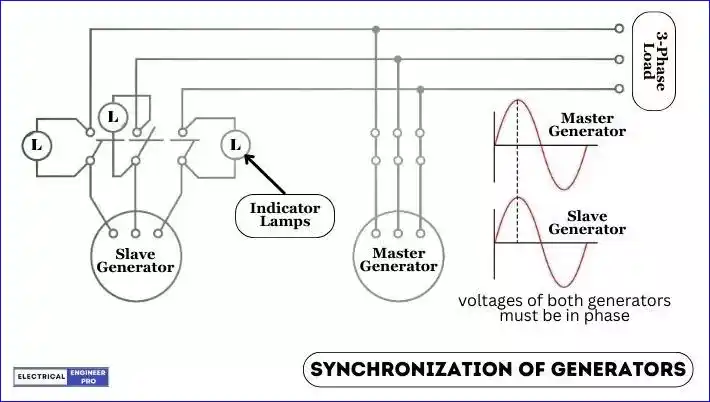

For example, let’s contemplate a scenario where one electric generator (master) is operating without any load, and we have to connect another electric generator (slave) in parallel.

So for connecting master and slave electric generators in parallel, it is crucial that the actual terminals to be connected should have equal potentials. This equalization prevents circulating currents between the generators.

As the voltage of a synchronous electric generator is alternating, the potentials of its terminals change continuously. Therefore, for successful parallel connection of a slave generator with a master generator, it is crucial that the instantaneous potential variations of the slave generator’s terminals precisely match those of the corresponding terminals of the master generator.

During the process of connecting both electric generators in parallel, the terminals of the two generators are connected to an indicator. This indicator senses the difference in voltages across the pairs of terminals to be connected.

When the voltages of both generators have the same waveform, frequency, magnitude, and phase sequence, the indicator reads zero, indicating that the slave generator can be connected in parallel. Some flexibility is allowed in cases where the frequencies are nearly identical.

If the slave generator operates at a slightly higher or lower speed than required, an inherent mechanism kicks in, causing the slave generator to equal its speed with that of the master generator. This equalization process of power slows down the faster generator and accelerates the slower one.

This process of connecting a slave electric generator in parallel with a master electric generator is termed as Synchronization of Generators.

Conditions for the Parallel Operation of Synchronous Electric Generators

So, for two synchronous electric generators to work in parallel smoothly, The following conditions should be met,

- The terminal voltage of the Secondary (slave) generator should match with the Primary (master) generator.

- The frequency of the Secondary (slave) generator should be same as the Primary (master) one.

- Ensure that the phase of the Secondary (slave) generator’s voltage is identical to the Primary (master) generator concerning the external circuit.

- Confirm that the phase sequence of the Secondary (slave) alternator’s voltage aligns with that of the Primary (master) generator.

Also Read: Explore the Diverse World of DC Motors

Role of Synchronous Electric Generators in power Systems

Synchronous generators play a crucial role in power systems, providing stability, reliability, and essential services to ensure the efficient generation and distribution of electrical energy. Here are key aspects of their role in power systems:

- Base Load Power Generation: Synchronous generators are often used as base load generators in power plants, providing a constant and continuous output of electrical power to meet the minimum demand on the electrical grid.

Good to Know: Base load generators are power plants that operate consistently at a high output level, providing a continuous and stable supply of electricity to meet the minimum or "base" level of demand on the electrical grid.

- Grid Stability and Synchronization: Synchronous generators help maintain the stability of the electrical grid by supplying synchronized power. Their ability to operate in parallel and synchronize with the grid frequency ensures a stable and balanced power supply.

- Reactive Power Support: Synchronous generators contribute reactive power to the power system, helping to regulate voltage levels and enhance the overall stability of the grid. This is critical for maintaining a reliable power supply.

- Frequency Regulation: Synchronous generators play a key role in frequency regulation. They adjust their speed to match the grid frequency, helping to ensure that the power system operates within acceptable frequency limits.

- Peak Load and Fast Response: Synchronous generators can quickly respond to changes in demand, making them suitable for providing peak load power during periods of high electricity demand.

- Grid Control and Ancillary Services: Synchronous generators provide essential ancillary services to the grid, such as frequency control, voltage regulation, and reactive power support. These services contribute to the overall reliability and efficiency of the power system.

- Interconnection of Power Plants: Synchronous generators facilitate the interconnection of multiple power plants within a region. They can operate in parallel, sharing the load and contributing to a reliable and integrated power supply.

- Islanding and Micro-grid Operations: Synchronous generators support the creation of microgrids and can operate in island mode, providing localized power generation and maintaining grid stability in isolated areas.

Island Mode: Islanding in a power system refers to a condition where a portion of the electrical network continues to operate in isolation from the main grid. This isolated section, or "island," functions independently and maintains its own generation and load balance even though it is disconnected from the larger power grid.

- Voltage Control: Synchronous generators contribute to voltage control by adjusting their excitation levels to regulate terminal voltage, ensuring that the power delivered to consumers meets voltage quality standards.

- Load Sharing and Parallel Operation: Synchronous generators can operate in parallel with other generators, sharing the load and contributing to a coordinated and efficient power generation system.

The role of synchronous generators in power systems is multifaceted, encompassing various functions that are critical for maintaining a reliable, stable, and well-controlled electrical grid.

Applications of Synchronous Electric Generators

Synchronous electric generators find applications in various industries and power systems due to their unique characteristics. Some common applications include:

- Power Generation in Power Plants: Synchronous electric generators are widely used for electricity generation in power plants, particularly in large-scale facilities.

- Prime Mover-Driven Generators: They can be coupled with different prime movers such as steam turbines, gas turbines, and diesel engines to convert mechanical energy into electrical energy.

- Hydroelectric Power Plants: Synchronous electric generators are employed in hydroelectric power plants where the kinetic energy of flowing water is used to rotate turbines connected to the generator.

- Standby Power Systems: Synchronous electric generators serve as backup power sources in critical facilities such as hospitals, data centers, and industrial plants to ensure uninterrupted power during outages.

- Parallel Operation in Power Grids: They are used in parallel with other generators to supply electricity to the grid. Synchronization ensures a smooth connection to the existing power system.

- Co-generation Systems: Synchronous generators play a role in co-generation setups, where they produce both electrical power and useful heat simultaneously.

- Renewable Energy Systems: In certain renewable energy applications, such as wind farms, synchronous generators are utilized to convert the rotational energy of wind turbines into electricity.

- Shipboard Power Generation: Synchronous electric generators are employed on ships to generate electrical power for propulsion systems, lighting, and other onboard equipment.

- Industrial Applications: They find use in various industrial applications where a stable and synchronized power supply is crucial for manufacturing processes.

- Isolated Power Systems: In remote areas or islands, synchronous generators are employed in isolated power systems to generate electricity locally.

The versatility and reliability of synchronous generators make them a crucial component in a wide range of applications across various industries and sectors.

FAQs

Why is a synchronous generator also called an alternator?

The term “alternator” is often used interchangeably with “synchronous generator” because both refer to machines that generate alternating current through rotor-stator synchronization.

What is the role of a prime mover in a synchronous generator?

The prime mover, such as a steam or gas turbine, drives the rotor of the synchronous generator, converting mechanical energy into the rotational motion necessary for electricity generation.

Can a synchronous generator operate as a motor?

Yes, a synchronous generator can be used as a synchronous motor when connected to an electrical power source, converting electrical energy into mechanical energy to drive a mechanical load.

Can a synchronous generator be used in renewable energy applications like wind or hydroelectric power?

Yes, synchronous generators are used in some renewable energy applications, particularly in large-scale wind turbines and certain hydroelectric plants where grid synchronization is important.

What role does excitation play in a synchronous generator?

Excitation controls the strength of the magnetic field in the generator. By adjusting excitation levels, operators can control the generator’s voltage output.

How is the reactive power controlled in a synchronous generator?

Reactive power is controlled by adjusting the generator’s excitation level. This influences the generator’s power factor and helps maintain a balance in the electrical system.

What is the significance of synchronous generators in power system stability?

Synchronous generators contribute to power system stability by providing inertia and regulating voltage, helping to maintain the balance between power supply and demand.

How is the voltage output controlled in a synchronous generator?

Voltage output is controlled by adjusting the excitation level of the generator, which influences the strength of the magnetic field and, consequently, the generated voltage.