Curious about how ISO 50001 can benefit your organization? This standard offers a practical approach to enhancing energy performance. By implementing ISO 50001 based Energy Management System, businesses can cut down on energy costs, improve their public image, meet regulatory standards, and make a positive impact on the environment.

Also Read: A Guide to Pump Efficiency Calculations for Energy Managers

What is ISO 50001

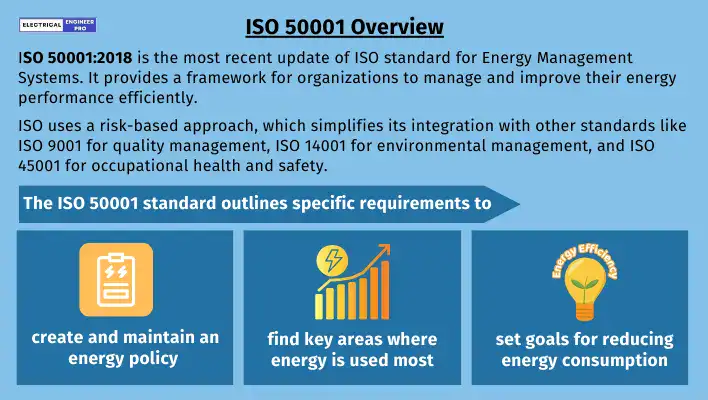

ISO 50001:2018 is the most recent update of ISO standard for Energy Management Systems. This standard outlines what an organization needs to do,

- to create and maintain an energy policy,

- find key areas where energy is used most, and

- set goals for reducing energy consumption.

The updated ISO 50001 aligns with the ISO High Level Structure and uses a risk-based approach, which simplifies its integration with other standards like ISO 9001 for quality management, ISO 14001 for environmental management, and ISO 45001 for occupational health and safety.

High-Level Structure (HLS) is a standardized framework designed to help create future ISO management system standards that work well together. It uses common terms, core text, basic definitions, and standard requirements to make different management systems compatible. This standardization makes it easier for organizations to integrate these systems, ensuring high quality and consistency in ISO standards.

To give you a clearer picture,

- ISO 50001 helps businesses manage their energy use more efficiently. This means not just cutting down on energy costs but also reducing their environmental impact.

- By following this standard, companies can better monitor their energy use, find ways to improve it, and ensure they are continually working towards more energy-efficient practices.

- Additionally, the alignment with other ISO standards makes it easier for organizations to manage various aspects of their operations, from quality and environmental impact to health and safety in one system.

Also Read: Energy Manager | Calculate Power Factor & Payback Period

Benefits of ISO 50001

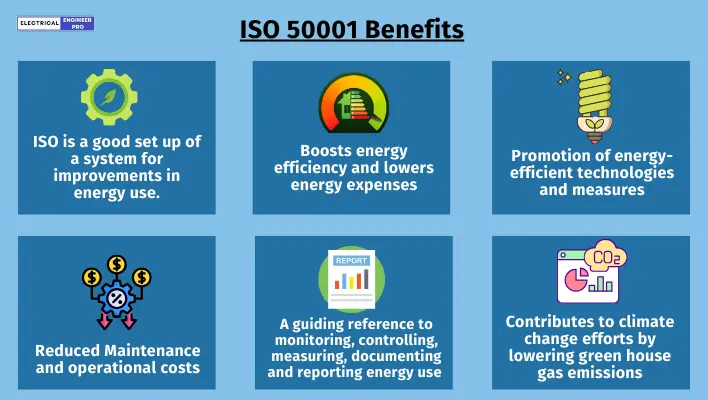

Implementing ISO 50001 effectively offers a structured way to enhance how organizations handle their energy use. It can change the entire approach to managing energy within a business.

- When companies incorporate energy management into their daily operations, they set up a system for ongoing improvements in how they use energy.

- By boosting energy efficiency and lowering energy expenses, businesses can become more competitive.

- ISO 50001 helps organizations contribute to climate change efforts by cutting down their energy-related greenhouse gas emissions.

- Promotion of energy-efficient technologies and measures.

- Maintenance and operational costs are reduced by efficient use of energy consuming assets.

- Monitoring, controlling, measuring, documenting and reporting energy use as per the standards gives a guiding reference to utilize energy efficiently.

Energy Management System (EnMS)

ISO 50001 is all about Energy Management Systems (EnMS). It provides guidelines on how to set up an Energy Management System (EnMS) to continuously improve energy performance.

Management System vs Energy Management System

In ISO 50001 “Management system” and “Energy management system” have different definitions. These definitions outline that you can’t have an Energy Management System (EnMS) without a management system in place.

Here’s how it is,

ISO defines Management System as a,

“set of interrelated or interacting elements of an organization to establish policies and objectives and processes to achieve those objectives.”

Which means a management system is a structured framework that helps an organization achieve its objectives through a coordinated set of interrelated or interacting elements.

And further defines Energy Management System as

“a management system to establish an energy policy, objectives, energy targets, action plans and process(es) to achieve the objectives and energy targets.”

The definition indicates that a Management system is part of the energy management system which institutes a structured approach within an organization to effectively manage energy usage and improve energy performance.

Analyzing both definitions, what we discover is that in ISO 50001,

- The management system is a fundamental component of the Energy Management System (EnMS).

- The management system provides a broad and comprehensive framework within which the EnMS operates.

- The Management System includes all the necessary elements to implement an energy management system that meets ISO 50001 standards.

- The management system focuses on taking action to manage energy effectively. While the EnMS defines the rules and procedures for achieving a company’s energy performance goals.

- At a company level, the management system oversees energy management activities, while the EnMS specifies how these activities should be carried out.

Also Read: Calculate motor temperature rise from unbalanced voltage | Energy Manager Exam question

Energy Management System (EnMS) Components

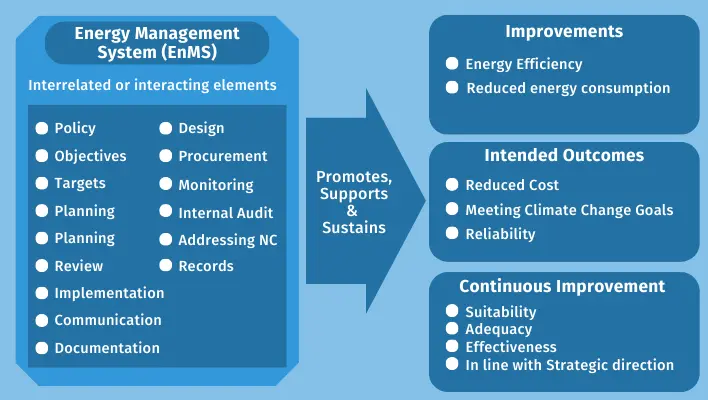

Now from the definitions it is clear that, Energy Management System contains a management system that has a structured framework which helps an organization achieve its objectives through a coordinated set of interrelated or interacting elements.

Interrelated and interacting elements are the components and processes that work together to manage energy performance and achieve energy-related objectives.

- Energy Policy: An official strategy from top management that outlines the organization’s commitment to improving energy performance. It guides the planning and implementation of the EnMS.

- Energy Objectives: Goals related to energy performance (e.g., reducing energy consumption by 15% over five years).

- Energy Targets: Measurable milestones that contribute to achieving the objectives (e.g., reducing energy use in the manufacturing process by 5% within one year).

- Energy Planning: Establishing energy performance indicators (EnPIs) and action plans to achieve the set objectives and targets.

- Energy Review: Analysis of the organization’s energy use and consumption to identify significant energy uses and improvement opportunities.

- Implementation and Operation: Ensuring that employees are receiving energy management training so they can implement procedures to control significant energy uses and ensure that operations are performed efficiently.

- Communication: The organization needs to communicate its energy policy, Energy Management System (EnMS), and energy performance with everyone in the company. All staff members should be communicated with the energy challenges and how their support is crucial in addressing them.

- Documentation: The information related to core elements of EnMS should be documented. Documentation in the form of digital or physical form serves as supporting evidence that demonstrates effectiveness and efficiency of EnMS.

- Design: When designing new, modified, or renovated facilities, the organization should think about opportunities to improve energy performance. These decisions can greatly affect how well the organization manages its energy use.

- Procurement: The organization should procure from vendors and suppliers whose services, products, and equipment align with its energy policy and objectives, while also considering cost and the quality of service or products provided.

- Monitoring, Measurement, and Analysis: Tracking energy performance by using Energy performance indicators (EnPIs), and analyzing data to ensure that objectives and targets are being met.

- Internal Audit: Conducting internal audits to verify that the EnMS conforms to the planned arrangements and is effectively implemented and maintained.

- Nonconformities and Preventive Action: Identifying and addressing nonconformities (non-compliance) and implementing corrective actions to avoid potential issues.

- Records: It’s important to maintain a thorough system for managing and preserving records that serve as evidence of actions taken. These records should be easily identifiable, organized, indexed, filed, stored, retrieved, and kept for an appropriate period of time.

- Management Review: Regular review of EnMS by top management that includes evaluating the need for changes to the policy, objectives, targets, and other elements.

By following these interrelated and interacting components, an EnMS ensures a systematic approach to managing and improving energy performance, ultimately leading to reduced energy consumption, cost savings and environmental benefits.

Also Read: How to find 3-phase AC motor parameters? Energy Manager exam question.

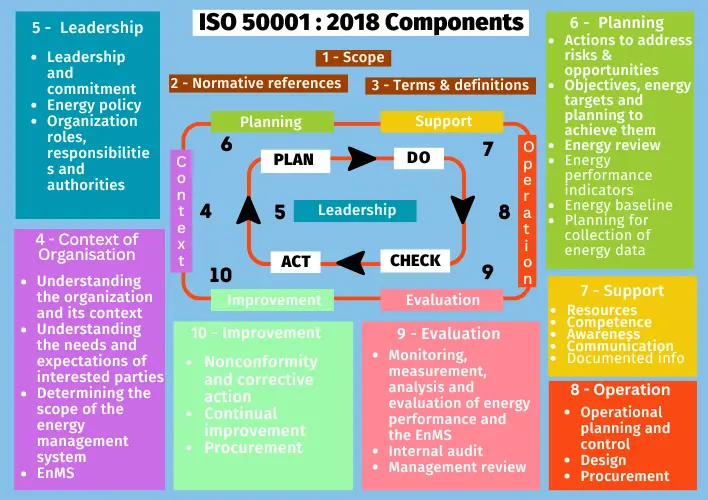

PDCA Cycle ISO 50001

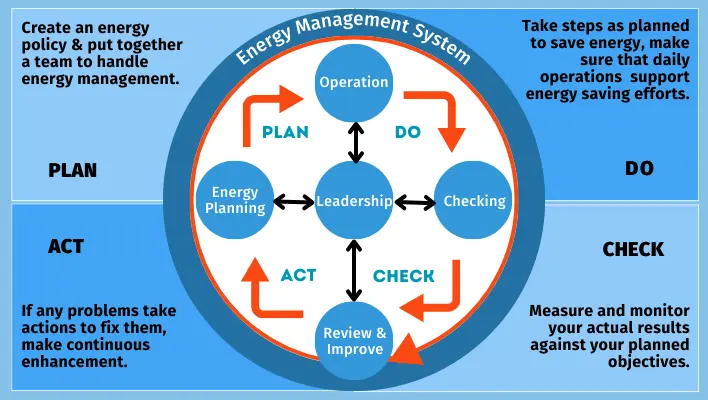

The Plan-Do-Check-Act (PDCA) cycle is a method used in ISO 50001’s Energy Management System (EnMS) to help organizations continuously improve their energy use and efficiency.

Plan: First, the organization takes a good look at how they use energy now and sets up a plan to improve. They create an energy policy, put together a team to handle energy management, and identify areas where they can save energy. They set goals and make detailed plans on how to achieve them.

Do: Next, they put their plan into action. This means carrying out the steps they’ve planned to save energy, making sure their daily operations and maintenance support these efforts, and spreading the word about their energy-saving plans to everyone in the organization. They also make sure that new designs and purchases are energy-efficient.

Check: Then, they monitor and measure how well they’re doing. They keep track of their energy use, analyze the data to see where they’re improving and where they’re not, and conduct internal checks to ensure everything is going according to plan. They regularly review their progress to make informed decisions.

Act: Finally, if there are any problems, they take action to fix them. They look for ways to keep improving their energy use and the overall system, making continuous enhancements to ensure they stay on track with their energy goals.

Also Read: Explore AT&C losses | BEE exam

ISO 50001 Components

ISO 50001 framework is similar to other well-known ISO standards like ISO 9001 for quality management and ISO 14001 for environmental management. They all follow the same basic approach called the plan-do-check-act cycle. Because of this shared foundation, it’s easy to integrate ISO 50001 with the other two systems.

The major sections of ISO 50001 are,

Scope

This section outlines requirements for creating, implementing, maintaining, and improving an Energy Management System (EnMS) to help organizations systematically enhance their energy performance.

The section also suggests that,

- Applies to any organization, regardless of type, size, location, or energy use.

- Covers activities affecting energy performance under the organization’s control.

- Requires continual energy performance improvement without specific targets.

- Can be used alone or integrated with other management systems.

Normative References

The updated ISO standard has removed the normative reference, but the clause heading is kept to maintain consistent numbering with other ISO standards.

Terms and Definitions

This section explains the terms and definitions used in the Standard, helping organizations understand and apply them. These terms & definitions are arranged in 5 subsections,

- Terms related to organization

- Terms related to management system

- Terms related to requirement

- Terms related to performance

- Terms related to energy

All the terms and definitions are listed in the way they appear in major topics like Context of the Organization, Leadership, and Planning, and listed in the order they appear in the Standard.

The sections 4 to 10 provide the requirements of the Standard. These sections are designed as per PDCA cycle to help organizations to apply EnMS efficiently.

Context of the Organization

In the updated version of ISO 50001:2018, this section was revised to enhance how organizations manage energy. The previous 2011 version ISO emphasized reviewing energy use, the new context stipulates that organizations understand their overall energy needs before focusing on specific energy uses or performance details.

The sub-sections are arranged in a way where we:

- first, understand the organization and its context (4.1); then,

- identify the needs and expectations of interested parties (4.2);

- use the information from 4.1 and 4.2 to determine the scope (4.3); and finally,

- design the Energy Management System (4.4).

Leadership

This clause deals with “top management,” the people who lead and control the organization at its highest level. Its aim is to demonstrate leadership and commitment by integrating the EnMS into the organization’s overall business strategy.

The following subsections in this clause emphasizes that the top management should demonstrate leadership by setting up the foundations for energy efficiency, establishing policies and frameworks, and defining clear roles and responsibilities to ensure effective implementation and continuous improvement of the EnMS within the organization.

- Leadership and Commitment: Leaders demonstrate commitment by setting energy efficiency goals, allocating resources, and integrating energy management into the organization’s strategy.

- Energy Policy: Leaders create and endorse an energy policy that outlines goals, responsibilities, compliance with regulations, and regular reviews to ensure effectiveness.

- Organization Roles and Responsibilities: Leaders define roles, responsibilities, and authorities for energy management, empower teams, ensure resources and training, and monitor performance for accountability and improvement.

Planning

This clause details how organizations plan actions to manage risks and opportunities. It emphasizes developing a planning process rather than a strict procedure to address various factors and associated risks.

The requirements include setting objectives and energy targets for the EnMS, and determining the funds and human strength needed to achieve them. It also involves conducting an energy review to assess the total energy used, establishing energy performance indicators, defining energy baselines, and creating an energy data collection plan.

Support

Support is one of the most important prerequisites to fulfill ISO requirements. This section focuses on the need for all necessary management system resources.

Organizations must identify the skills needed for roles that affect EnMS performance and ensure staff receive proper training. Everyone in the organization should know the energy policy, how their work affects it, and the consequences if they don’t follow the EnMS.

The section also covers “documented information,” which involves creating, updating, and controlling essential data.

Operation

This section covers,

- Operational Planning and Control: This section focuses on setting criteria to control processes related to Significant Energy Uses (SEUs), including operation and maintenance of facilities and equipment.

- Design: ISO 50001 does not mandate a comprehensive analysis of every stage of a product or process lifecycle in terms of energy use. However, It applies to designing new or renovated facilities and systems, encouraging the use of efficient technologies and renewable energy options.

- Procurement: This part requires organizations to establish criteria for evaluating energy performance when purchasing products and services that impact energy use. Suppliers must be informed that energy performance is a key factor in procurement decisions. Specifications for purchased equipment and energy should align with organizational energy policies and consider environmental impacts, even if the energy source is outside the EnMS scope.

Performance

Performance evaluation includes implementing the data collection plan and documenting improvements in both energy performance and the effectiveness of the Energy Management System (EnMS).

- Monitoring, Measurement, Analysis, and Evaluation of Energy Performance:

This section requires organizations to monitor and measure:

- The effectiveness of their action plans in achieving energy objectives and targets.

- Energy Performance Indicators (EnPIs).

- Operations related to Significant Energy Uses (SEUs).

- Actual energy consumption compared to expected levels.

Improvements in EnPIs over time indicate better energy performance, while significant deviations must be investigated. Data accuracy and consistency are important considerations during analysis.

- Evaluation of Compliance with Legal and Other Requirements:

Internal audits are crucial for ensuring continual improvement and verifying that the EnMS:

- Enhances energy performance.

- Meets internal requirements and aligns with the energy policy, objectives, and targets.

- Conforms to ISO 50001 standards.

Auditors should follow ISO 19011:2018 guidelines. Audit results, including any non-conformities, should be documented and communicated to stakeholders, including top management.

- Management Review:

Top management conducts Management Reviews to strategically evaluate EnMS performance. Reviews use factual EnMS data to recommend improvements. The process should be documented, covering key areas as outlined in the ISO 50001 standard.

Improvement

This clause requires organizations to continuously improve their Energy Management System (EnMS), ensuring it remains suitable, adequate, and effective. They must show ongoing improvements in energy performance. It involves taking corrective actions to address any issues and identifying opportunities for further EnMS enhancement.

Also Read: Cascade Efficiency Explained with Example

ISO 50001 Certification Process

Step 1: Introduction to ISO 50001 Certification Initiating ISO 50001 certification for your company begins with comprehensive awareness training. This step ensures all staff understand the standards and benefits of ISO 50001, crucial for their support and engagement.

Step 2: Analysis of Current vs Expected Performance: The next step is performing an analysis to pinpoint areas where your organization falls short of ISO 50001 requirements. This process involves evaluating your current energy management systems and comparing them to the ISO 50001 standards. Documenting these differences helps prioritize areas needing improvement, offering a clear focus for your future efforts.

Step 3: Framing ISO 50001 EnMS Following the analysis, the next step involves drafting an ISO 50001 Energy Policy and an Energy Management System (EnMS) project plan. This plan outlines timelines, milestones, and resource allocation for successful EnMS implementation. It should also contain all the processes such as ISO registration, internal and external audits, and details of necessary resources, such as personnel, budget, and tools, required to implement the EnMS effectively.

Step 4: Appointment of ISO Advisory Body (AB) Forming an ISO Advisory Body (AB), led by a primary coordinator and comprising departmental representatives, is crucial. The AB oversees EnMS design, monitors progress, resolves issues, and allocates necessary resources.

Additionally, the AB will be responsible for forming an energy task squad. This squad will consist of teams tasked with managing the EnMS process. Each team will have clearly defined roles and responsibilities, and will utilize regular meetings and collaboration tools to facilitate their work. These teams will report directly to the Advisory Body.

Step 5: Auditor Training Training is a vital component of the certification process. Continuous ISO education should be implemented to keep staff updated on best practices and any changes in standards, ensuring everyone is well-equipped to support the EnMS.

Internal Auditor Training: Staff members who are tasked with internal audits should be trained on both ISO 50001 and the specifics of ISO 50001 internal auditing.

Step 6: Documentation Framework Developing comprehensive documentation aligned with ISO requirements is pivotal. This includes procedures for document control and energy record management, ensuring accuracy, accessibility, and audit readiness.

Step 7: EnMS Implementation Once the documentation is complete, the next step is to implement your EnMS across the organization. This involves putting operational controls and procedures into action as per your documented EnMS.

Thoroughly record all procedures, processes, and evidence of compliance with ISO 50001 requirements. These documents, whether digital or physical, provide crucial support during internal and external audits, demonstrating the efficient implementation of ISO EnMS policies.

Step 8: Internal Audit Conducting rigorous internal audits before external certification audits is critical. These audits evaluate EnMS performance, identify non-conformities, and facilitate timely corrective actions.

Step 9: ISO 50001 Certification Audit Preparing for the external certification audit involves finalizing documentation and processes. A mock audit may precede this to simulate audit conditions and address any identified issues prior to the certification body’s assessment.

Step 10: Follow-up to External Audit In the event of serious non-conformities (NCs) identified during the Certification Audit, a follow-up visit will be scheduled by the external auditors. This on-site visit is aimed at ensuring that the identified NCs are effectively addressed through the implementation of suitable corrective actions.

Step 11: Surveillance Visits Post-certification, regular surveillance visits by the certification body monitor EnMS performance and compliance with ISO 50001. These visits ensure ongoing improvement and adherence to regulatory requirements.

Step 12: Renewal Audit Before the ISO 50001 certificate expires (typically every three years), a renewal audit evaluates continued compliance, improvements in energy management, and the effectiveness of EnMS controls.

This structured approach not only ensures ISO 50001 compliance but also enhances organizational energy efficiency and sustainability practices.

Advantages & Disadvantages of ISO 50001

| Advantages | Disadvantages |

| Encourages energy savings and cost reductions. | Internal and external costs during system preparation. |

| Enhances visibility and stakeholder confidence. | Proliferation of new ISO standards. |

| Facilitates integrated management approach. | Potential over-regulation and increased documentation needs. |

| May become a market requirement, enhancing competitiveness. | Recertification obligations every three years. |

| Non-energy-related management improvements. | |

| Signals commitment to energy management. |

ISO 50001 FAQs

Is ISO 50001 mandatory?

ISO 50001 certification is voluntary and not legally required in most countries. However, organizations may choose to implement the standard to benefit from improved energy performance, cost savings, and competitive advantages.

What is the validity period for ISO 50001 certification?

ISO 50001 certification is valid for three years. During this period, organizations undergo surveillance audits to ensure continued compliance with the standard’s requirements. Recertification audits are conducted after three years to renew certification.

How does ISO 50001 help organizations save energy?

ISO 50001 provides a systematic approach to energy management, including establishing energy policies, setting energy objectives and targets, implementing action plans, and monitoring performance. This structured approach helps organizations identify and implement energy-saving opportunities.

Who can implement ISO 50001?

ISO 50001 is applicable to any organization, regardless of size, type, or sector. It is particularly beneficial for organizations that consume significant amounts of energy and want to improve their energy efficiency.

Who is allowed to carry out an ISO 50001 certification?

ISO 50001 certification must be carried out by accredited certification bodies. These bodies are independent organizations that have been accredited by an Accreditation Body (such as ANSI, UKAS, DAkkS, etc.) to assess organizations against the requirements of ISO 50001.

Can ISO 50001 be implemented with other standards?

ISO 50001:2018 can be integrated seamlessly with other standards. This structure ensures consistency in documentation, policies, procedures, and processes across multiple standards, facilitating easier implementation and alignment with organizational objectives.