High-Voltage Direct Current (HVDC) transmission is steadily reshaping how we move electricity across long distances.

Unlike conventional alternating current (AC) systems, HVDC uses direct current to reduce energy losses during transmission, making it ideal for delivering power from remote generation sites such as offshore wind farms or large-scale solar parks to major cities and industrial centers.

Its ability to connect distant and often variable renewable energy sources to stable grids has become increasingly relevant in today’s transition toward low carbon energy systems.

HVDC transmission has been used in a range of critical applications:

- Transfer of power from point to point over long distances.

- Underwater (sea) transmission.

- Interconnection of two AC systems with two distinct frequencies.

- Improving power system stability as a parallel connection with the current AC system.

This post focuses on the recent advancements in HVDC transmission. We’ll look at its core components, evolving technologies and the growing importance of HVDC in creating sustainable and flexible power networks.

But first, it’s important to understand what HVDC transmission is, why HVDC matters and what makes it indispensable to the future of electricity delivery.

Also Read : Power Supply System | A Comprehensive Guide

Historical Background and Evolution of HVDC

DC power systems have been around since the late 1800s, with Thomas Edison’s early work in low voltage distribution. But by the early 20th century, AC transmission invented by Tesla and promoted by Westinghouse became the standard because of its efficiency over long distances.

The modern era of high-voltage DC (HVDC) began in 1954 with the Sweden–Gotland project. This was the first commercial HVDC link, using mercury arc valves to transmit power through a submarine cable. It proved that DC could be used effectively for bulk power transmission.

The 1970s brought a significant upgrade with the introduction of thyristor valves, which replaced mercury arc technology. These formed the basis of Line Commutated Converter (LCC) HVDC systems, making large-scale DC projects more practical and reliable.

In the 1990s, Voltage Source Converters (VSCs) were introduced. These allowed for better control of power flow and made it possible to connect weak grids or renewable sources.

A decade later, Modular Multilevel Converters (MMCs) advanced the technology further by reducing energy losses and eliminating bulky filters.

In recent years, countries like China have built multiterminal HVDC systems, and Europe is exploring DC grids to integrate offshore wind and cross border power exchange.

With improvements in DC breakers and protection systems, HVDC is becoming a core part of modern power networks. Today, HVDC is crucial for long-distance renewable energy transmission and offers a reliable solution where traditional AC lines face technical or environmental limits.

Also Read : Importance of Power Transmission Lines | Explained

Importance and Advantages of HVDC Transmission

The technological development of high voltage DC transmission technology greatly transformed the method of bulk power transfer over long distances, especially when transmission distance is more than 500 km.

Let’s see more why HVDC is important in power systems:

1. Efficient Long-Distance Transmission

HVDC transmission is most advantageous for moving large amounts of power over long distances, either through overhead lines or submarine cables. Also, with no capacitive losses like AC lines, HVDC transmission delivers power more efficiently, making it ideal for undersea connections to islands and distant regions.

2. Asynchronous Interconnection of Power Grids

High voltage DC transmission has the ability to tie together two AC grids with different frequencies. This enhances inter-regional as well as international inter-connectivity of the grid.

3. Lower Transmission Losses

HVDC systems transmission losses are lower than HVAC, particularly over long distances. Thus promoting increased overall system efficiency as well as cost-effectiveness.

4. Improved Power Flow Control

HVDC allows real-time, accurate control of power flow, independent of system impedance, voltage, or frequency.

5. Stability and Damping of Oscillations

HVDC links improve stability in weak AC grids by damping oscillations, reducing fault currents, and reinforcing system strength for renewable integration.

6. No Increase of Short-Circuit Levels

Unlike AC links, HVDC connections do not increase short-circuit currents, allowing existing protection systems to remain sufficient without major upgrades.

7. Better Voltage Regulation

HVDC transmission eliminates reactive power issues, ensuring better voltage regulation and stable voltage profiles by avoiding problems like the Ferranti effect.

8. Increased Power Transfer Capability

More power is delivered for the same size of the conductor through HVDC systems than through AC systems. This feature maximizes the utilization of transmission lines as well as minimizes the quantity of materials.

9. ROW Optimization

HVDC’s smaller land footprint (Right of Way) lowers environmental impact and makes land use easier in crowded or sensitive areas.

Next, let’s understand the working principle of HVDC transmission.

Also Read : What is interconnected power system or grid?

Working Principle of HVDC Transmission Station

An HVDC transmission system is composed of several interconnected sections, each playing a specific role in the conversion and transfer of electrical power.

Main Sections of an HVDC Transmission System:

- AC Side Converter Transformer (Step-up)

- Rectifier Station (AC to DC Conversion)

- DC Transmission Line (Overhead or Cable)

- Inverter Station (DC to AC Conversion)

- AC Side Converter Transformer (Step-down)

The process begins at the sending end, where a converter transformer steps up the AC voltage from the generating station to a higher level suitable for conversion.

This high-voltage AC power is then fed into a converter station, where it is rectified into direct current (DC) using power electronic devices such as transistors or IGBTs.

Once converted, the DC power is transmitted through overhead lines or underground cables to cross-country links or submarine interconnections.

At the receiving end, a second converter station takes the transmitted DC and converts it back to AC using an inverter. The output AC is then stepped down through another converter transformer to match the voltage levels required for local distribution.

Also Read : Smart Grid | The Ultimate Guide

What are HVDC Links & its types

HVDC links are nothing but how the converter stations and transmission lines are arranged to facilitate power flow between two or more points.

Each configuration has a specific structure based on the needs of distance, capacity, reliability, and system characteristics.

In HVDC systems, the “link” defines the way the system is physically and electrically connected, including:

- Number of conductors used (one, two, or more).

- Direction of current (unidirectional or bidirectional).

- Use of ground or dedicated return conductors.

- Point-to-point or multi-terminal interconnections.

Thus, the HVDC link configuration determines the performance, redundancy, flexibility, and cost of the transmission system.

Common Configurations of HVDC Links are as follows,

Monopolar High Voltage Direct Current (HVDC) link

A Monopolar link is a very simple and economic solution for power transmission over a long distance. It comprises two converter stations located at the sending and receiving ends and a sole DC transmission line of high voltage (the “pole”) between them. Either the positive or the negative DC voltage is applied with respect to the earth potential.

The earth or sea provides the return path for the current and eliminates the necessity for a return conductor, thus making the system easier to design and cheaper to install.

For instance, most undersea power cables between islands or nations have a monopolar system because of the fact that it’s cost-efficient and practically enough for the length of transmission.

Monopolar designs are planned with provisions for upgrade to bipolar configurations so the transitions towards smart grids, large-scale renewable integration and international connections are easy to achieve.

Bipolar High Voltage Direct Current (HVDC) link

Bipolar link consists of two independent monopolar systems operating at different polarities, namely one at positive voltage (+V) and the other at a negative voltage (V) relative to ground.

These two poles collaborate for effective transmission over long distances mainly by overhead lines.

By definition, a bipolar system comprises two monopolar connections of opposite potentials which are connected in a parallel configuration.

How It Works:

- Under normal conditions, equal currents flow through both poles, and ground return current is nearly zero.

- If one pole fails, the system switches to monopolar mode, using the ground or a metallic return to maintain about 50% of its transmission capacity, ensuring reliability.

Homopolar High Voltage Direct Current (HVDC) link

A Homopolar link has two or more conductors carrying the same polarity (either positive or negative) of voltage relative to ground. The return of the current path is facilitated by the ground or sea.

Unlike bipolar systems, where conductors carry currents in opposite directions, in a homopolar setup, all conductors carry current in the same direction, with the ground acting as the return path.

While not commonly used today due to environmental issues and advances in technology, homopolar links are still significant in HVDC theory and history, particularly for specialized or experimental uses.

Back-to-Back High Voltage Direct Current (HVDC) connection

A Back-to-Back configuration has the location of both the rectifier (AC/DC converter) and the inverter (DC/AC converter) at the same location, without the presence of a long-distance DC line connecting them.

The DC link between the two converters is very short, typically a matter of a few metres.

In this configuration, two AC systems that might be of the same frequency or of different frequencies (asynchronous systems) are connected through a short DC intermediate stage.Therefore, it is an AC-to-AC connection achieved by means of DC isolation and regulation.

Back-to-Back HVDC is a key technology for the stable, controlled, and efficient interconnection of asynchronous or geographically dispersed AC networks.

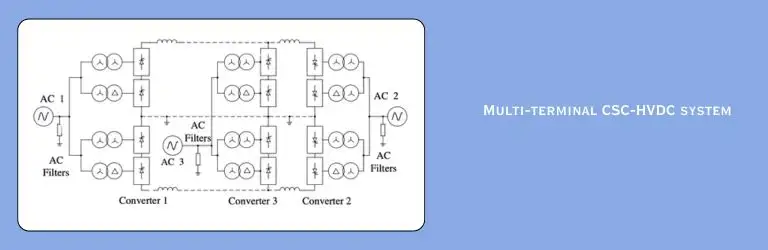

Multi-terminal High Voltage Direct Current (MTDC) connection

A MTDC configuration has three or more converter stations connected by a common DC transmission grid.

Unlike the two-terminal traditional point-to-point HVDC installations, MTDC installations enable the multiple converters to work as individual rectifiers (injecting power) or inverters (withdrawing power) as required by instantaneous operational conditions.

This layout makes HVDC a dynamic, flexible and robust DC grid that facilitates long and diverse power exchange between power-generation hubs.

How a Multi-terminal HVDC Link Works

Dynamic role switching: Converters 1 and 3 function as rectifiers supplying DC power and Converter 2 as an inverter withdrawing power; or the reverse as the situation demands.

Flexible Power Routing: Power could be routed dynamically between regions according to load conditions, availability of generation and stability conditions of the grid.

Complex Control Architecture: Needs complex control apparatus as well as quick communication between terminals for timely operation and fault handling.

The MTDC link is the next level of HVDC technology, going beyond point-to-point connections towards completely interconnected intelligent DC networks.

Components of HVDC Systems

The essential parts of an HVDC transmission system depend on factors such as the type of converter technology used, the system’s rated DC voltage, and its power handling capacity.

• Converter

Converters serve the fundamental role of changing electrical energy from one form to another. At the transmission end, they convert alternating current (AC) into direct current (DC). At the receiving end, a similar unit performs the reverse operation, turning DC back into AC for local distribution.

Typically, an HVDC system includes two such converter stations, one acting as a rectifier to send power and the other functioning as an inverter to receive and reintegrate it into the AC grid.

The converter design depends on the type of HVDC technology being used. The two most common types are:

- Line Commutated Converters (LCC): Use thyristors as switching elements. These are typically used in bulk power transmission.

- Voltage Source Converters (VSC): Use insulated gate bipolar transistors (IGBTs) and offer greater control flexibility, especially in systems with weak AC networks or renewable integration.

Each converter is built using power electronic bridges that contain multiple valve arms. These valve arms are composed of several switching devices like thyristors or IGBTs. The quantity of these devices depends on the voltage and power rating of the system.

- For high voltage handling, devices are connected in series.

- For high current applications, devices are arranged in parallel.

For instance, a 500 kilovolt HVDC link rated for thousands of megawatts may include hundreds of switching elements, each precisely arranged to manage electrical stress and heat dissipation.

The number of converters in an HVDC station depends on the system layout. In basic arrangements like monopolar or bipolar links, one or two converters are installed at each terminal.

More complex designs, such as those found in multi-terminal networks or back to back stations, may include additional converters to manage power flow between multiple grid points.

In modern voltage source systems, they allow for independent control of active and reactive power, support weak grids, and enable integration of renewable energy sources such as offshore wind farms.

• Converter transformer

A converter transformer is an important part of an HVDC system, located between the AC network and the converter station. It adjusts the AC voltage to the level required by the converter and provides electrical isolation between the AC and DC sides.

These transformers differ from standard AC transformers due to their exposure to a combination of AC, DC, and transient over voltages. The insulation system must handle these stresses such as polarity reversals and the potential between valve windings and ground.

Converter transformers also deal with high harmonic content caused by the switching nature of converters. This generates additional leakage flux, thereby creating local hot spots in the windings. To manage this, they are provided with magnetic shunts, directed oil flow and extra cooling systems.

To precisely control the impedance on load tap changer (OLTC) are provided because even small variations can affect the cost and performance of DC terminal equipment. OLTCs regulate voltage, adjust firing angles and support both rectifier and inverter operation. They allow fine tuning of the output voltage in small steps, which is critical for system stability.

Converter transformers also serve as galvanic barriers, preventing DC currents from flowing into the AC system. Their performance directly influences the availability and reliability of HVDC transmission.

• Smoothing reactors

Smoothing reactors primary function is to reduce ripple in the DC current, ensuring a more stable and continuous current flow.These reactors also play a protective role in conjunction with DC filters.

During events such as commutation failures, when the converter fails to properly transfer current between valves, smoothing reactors help limit the rate at which fault currents rise. By doing so, they protect sensitive converter components from sudden electrical stress.

Smoothing reactors also contribute to reducing electromagnetic interference and improving the quality of power delivered. Their design is optimized for high inductance with minimal loss, making them effective in both monopolar and bipolar HVDC systems.

• Filters

In HVDC transmission systems, filters manage harmonics generated by the switching action of power electronic devices such as thyristors.

During converter operation, the repetitive firing of thyristors produces harmonics that can enter the connected AC network. If left uncontrolled, these harmonics may lead to equipment overheating, degraded power quality and interference with nearby communication systems.

Further harmonics are also created because of unbalanced transformer reactance, voltage asymmetries in the AC supply, or errors in the firing angle of converter phases. These result in unpredictable harmonic profiles, making effective filtering essential for system stability and reliability.

To address these challenges, HVDC systems employ three main types of filters:

1. AC Filters

AC filters are passive components installed on the AC side of the converter station. Their role is to divert harmonic currents away from the grid by providing low-impedance paths at specific harmonic frequencies. They may be tuned to eliminate individual harmonics or designed as damped filters to target a broader frequency range.

2. DC Filters

DC filters serve a similar purpose on the DC side of the converter. They are used to reduce harmonic content in the DC current, thereby minimizing ripple and protecting both the converter equipment and downstream components.

3. High-Frequency Filters (RF/PLC Filters)

High-frequency filters are designed to suppress radio frequency and power line carrier (PLC) interference. These filters are typically installed between the converter transformer and the AC bus, or along the high-voltage DC bus and neutral connections. Their function is to block high-frequency disturbances from affecting control systems or external communication networks.

• Reactive Compensation.

Converter stations in HVDC systems consume reactive power due to the firing angle delay during AC to DC conversion. Since the DC side neither generates nor uses reactive power, compensation is needed on the AC side to maintain voltage stability.

This is typically achieved using shunt capacitors placed at both converter terminals. The level of compensation required depends on the Short Circuit Ratio (SCR) of the connected AC system. In weak grids with low SCR careful selection of reactive compensation is critical.

In such cases, fixed capacitors may be supported by dynamic devices like SVCs or STATCOMs to ensure stable operation, improve voltage control, and support system reliability.

• Power transmission lines

HVDC transmission lines can be constructed using either overhead conductors or underground and undersea cables.

Overhead lines are more common due to their lower cost and ease of installation. These conductors are suspended from towers or poles and are typically uninsulated. However, they face challenges such as line sag, mechanical tension, thermal expansion under heavy loading, and reduced capacity under adverse weather conditions.

But underground and undersea cables are fully insulated and used in areas where overhead lines are impractical, such as urban zones, water crossings, or environmentally sensitive regions.

Though more expensive, they offer better protection against weather-related disruptions like wind and ice, making them a preferred option for reliability in critical applications.

• Earthing Electrodes

Earth electrodes are vital components in monopolar HVDC systems, where they carry continuous current during normal operation. They offer a cost-effective alternative to installing a second conductor, particularly in low-power or short-distance applications.

These electrodes are also used in bipolar and multi-terminal HVDC systems, where they serve as a common reference point for defining system voltage. This reference is essential for insulation coordination and over-voltage protection.

In bipolar systems, although both poles ideally carry equal and opposite currents, slight imbalances are unavoidable. As a result, a small differential current flows through the station’s neutral point to ground. To prevent corrosion and localized ground heating, it is standard practice to place earth electrodes away from the converter station, connected by a dedicated conductor.

• Protection equipment

To ensure operator safety during preventive maintenance and equipment servicing, HVDC systems are equipped with several protective devices. These include disconnecting switches installed in series with the HVDC lines, grounding switches, and AC and DC circuit breakers. Together, these components help isolate equipment, discharge residual voltages, and prevent accidental energization during maintenance activities.

When and Why HVDC Is Used

High Voltage Direct Current (HVDC) is used in power transmission where traditional Alternating Current (AC) systems face limitations. While AC is widely used in local and regional grids, HVDC becomes the better option in specific situations.

Why Use HVDC Instead of AC?

Firstly, HVDC is not a replacement for AC systems but a strategic solution for challenges that conventional transmission methods cannot address efficiently.

AC transmission lines have natural electrical properties like inductance and capacitance. These properties limit how far electricity can travel, especially through underground or underwater cables. In many cases, AC cables can only carry power efficiently for about 40 to 100 kilometers. Beyond that, energy losses and voltage problems become too high.

HVDC does not have these issues. It can carry power over much longer distances with lower losses and better efficiency. Since there is no reactive power in DC systems, the entire cable is used effectively to carry current. This makes HVDC the only practical solution for many long cable routes across oceans or into crowded cities.

HVDC is also useful for connecting power systems that are not synchronized. Different countries or regions may use grids that run at different frequencies. AC systems cannot be directly connected in such cases, but HVDC provides a stable link between them.

Another benefit of HVDC is the ability to control power flow accurately. This helps balance the grid and can prevent problems from spreading during faults or sudden load changes.

When Is HVDC the Right Choice?

HVDC is typically used when:

- Power needs to be sent over very long distances, usually more than 500 kilometers by overhead line or over 50 kilometers by cable

- A route must cross water bodies or pass through dense urban areas where underground cables are required

- Two power grids need to be connected without synchronization

- AC systems are too weak or unstable to handle more power flow

Environmental and Economic Advantages

HVDC lines require fewer conductors and narrower routes. This means less land is used, less visual impact, and lower costs for land acquisition. In many places, HVDC allows higher capacity transmission without building new corridors.

Although HVDC stations cost more at the start, the overall cost becomes lower for long distances. The system uses less energy and needs fewer components to manage power over the route.

Limitations and Disadvantages of HVDC Systems

While HVDC transmission offers clear benefits for long-distance and bulk power transfer, it also comes with several practical and technical challenges.

High Converter Station Cost: The biggest disadvantage is the high capital cost of converter stations. The requirement of specialized components like thyristor valves, cooling systems and filters makes the setup costly. Hence for shorter distances AC systems are more economical.

Harmonic Distortion and Filtering Needs

HVDC converters generate harmonics and non-sinusoidal currents on the AC side. This can cause electromagnetic interference and audio frequency disturbances. To manage this, large harmonic filters are required on both AC and DC sides of the station, leading to system complications and space constraints.

No Reactive Power Support

HVDC converters need reactive power compensation. Static VAR compensators (SVCs) or synchronous condensers are needed at both ends of the line to stabilize voltage and maintain system performance.

Voltage Transformation Difficulties

HVDC systems cannot use transformers to step up or step down voltage directly. To change the voltage DC needs to be converted to AC. Voltage is changed using transformers and converting it back to DC if needed.

Challenges in Fault Isolation

Reliable HVDC circuit breakers are still under development. Current systems depend on converter gate control to interrupt fault currents, which is slower and less robust than conventional AC protection. This limits the scalability of multi-terminal HVDC networks.

Control System Complexity

HVDC control systems are more complicated than HVAC. Advanced control strategies and digital communication technologies are required for fast operations, ensure stability during fault conditions and to coordinate real-time data from multiple stations.

Conclusion: Why HVDC Matters for the Future

High Voltage Direct Current (HVDC) isn’t just an alternative to AC transmission, it’s becoming essential for the way we move electricity across continents, oceans and complex energy grids. As the demand for cleaner and more reliable power continues to grow, HVDC systems offer solutions that traditional AC systems struggle to provide.

One of the clearest reasons HVDC stands out is its ability to transfer large amounts of electricity over long distances without the losses typically seen in AC lines. This has huge implications for renewable energy.

Offshore wind farms, for instance, are often located far from where the electricity is actually needed. HVDC makes it possible to bring that power back to shore efficiently.

A good example is the North Sea Link between Norway and the UK. It uses HVDC to connect hydroelectric energy from Norway to the UK grid, balancing supply and demand between two very different energy systems.

HVDC is also critical in connecting grids that are not synchronized. Countries or regions with different operating frequencies or system standards can still share energy when linked through DC. This is important in a world where energy must be flexible, especially during emergencies or peak demand periods.

Another growing need for HVDC answers is urban space and environmental sensitivity. Because HVDC lines require less space and generate lower electromagnetic interference, they’re more suited for crowded urban corridors or underwater installations. Projects in India, China and Brazil are already using this advantage to connect remote generation sites to major cities.

Looking ahead, the development of multi-terminal HVDC networks and improvements in converter technologies will make these systems more responsive and scalable. As grids evolve into smarter, more decentralized systems, HVDC will play a vital role in maintaining stability while accommodating more solar, wind, and distributed storage.

In short, HVDC is not a futuristic concept but it’s already shaping the modern grid. It fills in the gaps that AC systems cannot and supports the transition to cleaner, more reliable and more flexible energy networks.

For power engineers, planners,and policymakers, understanding HVDC is no longer optional. It’s a key part of building the resilient energy systems the future will demand.

HVDC FAQs

What makes HVDC better than traditional AC transmission for long distances?

HVDC minimizes transmission losses over long distances, especially beyond 500 km. It doesn’t suffer from reactive power losses like AC and is ideal for undersea cables and remote power integration.

Is HVDC the future of power transmission?

Yes, HVDC is becoming increasingly critical due to the rise in renewable energy, intercontinental power trading, and the need for efficient, high-capacity transmission over vast distances.

Can HVDC systems be integrated with renewable energy sources like wind and solar?

Absolutely. HVDC is highly compatible with variable renewables, enabling efficient power evacuation from offshore wind farms and remote solar parks to urban load centers.

How are harmonics managed in HVDC systems?

Both LCC and VSC systems generate harmonics that can affect nearby equipment. These are mitigated using AC and DC filters, phase-shifting transformers, and optimized switching strategies.

How is power flow controlled in HVDC links?

In LCC systems, control is achieved by adjusting the firing angle of thyristors. In VSC systems, Pulse Width Modulation (PWM) is used to precisely control the magnitude and direction of power flow.

Why are converter transformers different from regular power transformers?

Converter transformers handle high harmonic content and DC bias. They are specially designed with interleaved windings, insulation systems, and shielding to withstand the electrical stress of converter operation.