In the vast array of circuit breakers, air circuit breakers (ACB) hold a special place. Imagine trying to manage low voltage electrical distribution without them, it would be quite a challenge! These multi-function devices are crucial not only for low voltage applications but also for medium voltage systems.

In today’s post, we’ll examine the world of ACBs that operate up-to or below 1000 V AC, exploring their working principles, various types, different parts, how to select the right one, and their standout features.

By the end of this post, you’ll have a solid understanding of why air circuit breakers are essential and how they make our lives a little bit easier. Let’s get started!

Also Read: Types of High Voltage Circuit Breakers | Explained

What is Air Circuit Breaker (ACB)

An Air Circuit Breaker (ACB) is an essential device in the world of electrical protection. It’s used to protect electrical circuits from overloads, short circuits and earth faults, especially in low voltage (LV) panels in substations and main distribution boards. It ensures that electrical systems operate smoothly and safely, in both auto and manual modes.

To elaborate, an ACB works to either make (close) or break (open) a circuit. Imagine it like the light switch in your house that turns your lights on and off. However, an ACB is more than a switch and has multi-function capabilities.

While your household switch just controls the lights, an ACB provides critical protection and can handle circuits where large currents are necessary to power heavy equipment.

Air circuit breakers (ACBs) are essential for not only turning electrical circuits on and off but also for automatically interrupting the flow of electricity when a fault occurs. This automatic interruption helps prevent damage and ensures safety.

But you might be wondering, where does the “Air” come into the picture?

In air circuit breakers, air is the arc-quenching medium. When the circuit is interrupted, a bright, hot electric arc forms between the contacts.

This arc is essentially a discharge of electricity through the air, and if it’s not managed properly, it can cause significant damage to both the electrical system and the circuit breaker itself.

Air plays a crucial role in managing this arc. As a medium, air absorbs the intense heat from the arc, thus cooling it down. The cooler the arc becomes, the easier it is to extinguish.

Additionally, ACBs are designed with arc splitters that work in conjunction with the air to divide the arc into smaller, more manageable segments. These smaller arcs are less intense and more easily quenched.

By efficiently cooling and splitting the arc, air ensures that the ACB can safely interrupt the electrical flow, protecting the system from potential hazards and maintaining overall safety.

Also Read: What is interconnected power system or grid?

Air Circuit Breaker (ACB) Construction

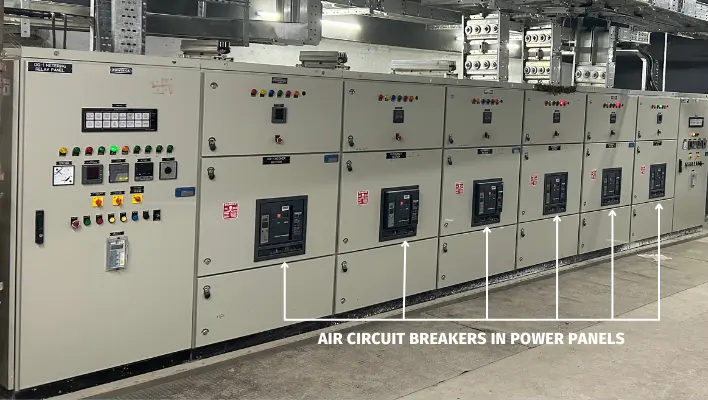

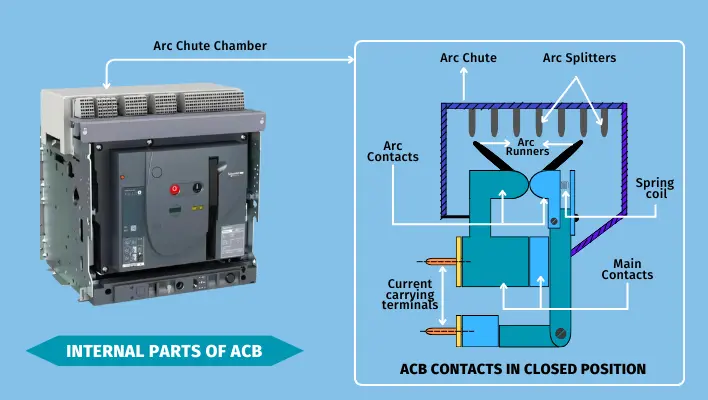

The above picture shows the normal arrangement of the Air Circuit Breaker (ACB). It has external and internal parts.

Internal Parts

Here are the functional details and features of the internal parts of an Air Circuit Breaker (ACB). Each of these parts play an important role in the functionality and performance of an ACB, ensuring safe and reliable interruption of electrical faults.

Main Contacts: The main contacts are responsible for conducting the load current under normal operating conditions and are designed to handle the rated continuous current of the breaker.

These contacts are made from high-conductivity materials like copper or copper alloys, often with silver plating to reduce contact resistance and improve conductivity.

They are durable and capable of withstanding mechanical wear and tear, designed to make or break the circuit with minimal electrical resistance and heat generation.

Arcing Contacts: Arcing contacts engage first during the closing operation and disengage last during opening to protect the main contacts from arc damage. They handle the electrical arc that forms when the breaker opens under load.

Made from arc-resistant materials like tungsten or molybdenum, arcing contacts are positioned to absorb the brunt of the arcing, prolonging the life of the main contacts. They are replaceable, as they wear out faster than the main contacts due to repeated arcing.

Arc Chute: The arc chute is a device that cools and extinguishes the electrical arc formed when the contacts open. It directs the arc into a series of metal plates called arc splitters, which split and cool the arc.

They are made from arc-resistant materials such as ceramic or specific composite materials. The arc chute contains metallic plates or grids that absorb and dissipate the arc energy. It enhances breakers performance by rapidly extinguishing the arc and minimizing the arc duration.

Arc Runners: Arc runners lead the electrical arc into the arc chute, helping in directing the arc away from the contacts to the arc chute for effective quenching.

Typically made from conductive materials like copper or aluminum, arc runners are shaped to encourage the arc to move quickly away from the contacts.

Arc Splitters: Arc splitters are also known as arc quenching plates, which divide the arc into smaller segments to facilitate faster cooling and extinction. They increase the surface area over which the arc is spread, helping to dissipate the energy.

Made from ferromagnetic or non-ferromagnetic metallic plates, arc splitters are arranged in a stack to create multiple narrow gaps for the arc to split into.

Spring Coil: The spring coil provides the necessary mechanical force to open and close the breaker contacts. It stores potential energy when the breaker is set (closed) and releases it to rapidly open the contacts during tripping.

Made from high-tensile steel or other suitable spring materials, the spring coil is designed to provide consistent and reliable force over numerous operations. It ensures rapid and reliable operation of the breaker during fault conditions.

Current carrying terminals: Current carrying terminals are the connection points for incoming and outgoing electrical conductors. They ensure a secure and stable electrical connection for the flow of current through the breaker.

These terminals are made from high-conductivity materials like copper or brass, often with surface treatments to prevent corrosion. They are designed to accommodate various types and sizes of conductors and feature robust construction to ensure long-term reliability and minimal contact resistance.

Also Read: Smart Grid | The Ultimate Guide

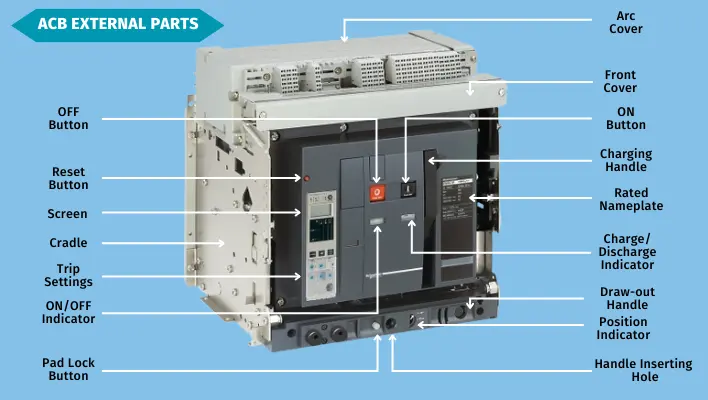

External Parts

Trip Settings / Relay: The trip relay is a safety component that automatically disconnects the circuit breaker during abnormal conditions like over-current or short circuits. It senses the fault and triggers the mechanism to open the breaker, protecting the electrical system from damage.

OFF Button: The OFF button is used to manually open the circuit breaker, disconnecting the electrical circuit. It allows for safe maintenance and emergency shutdowns.

ON Button: The ON button is used to manually close the circuit breaker, connecting the electrical circuit. It restores power flow through the breaker after it has been tripped or turned off.

Reset: The reset button is for safely restoring power after a trip, ensuring that any faults are addressed before the circuit is re-energized.

Charging Handle: The charge handle is used to manually charge the spring mechanism that operates the circuit breaker. This stored energy is used to quickly open or close the breaker.

Rated Nameplate: The rated nameplate displays the breaker’s electrical ratings, including voltage, current, and interrupting capacity. It provides essential information for proper installation and operation.

Charge/Discharge Indicator: The charge/discharge indicator shows whether the spring mechanism is charged (ready to operate) or discharged (needs charging). It ensures that the breaker is prepared for use.

ON/OFF Indicator: The ON/OFF indicator visually shows the current state of the breaker, whether it is in the on (closed) or off (open) position. This provides a quick reference for the operational status.

Arc Cover (Zero Arc Space): The arc cover encloses the arc chute and other internal parts to contain and extinguish the electrical arc generated during the operation of the breaker. It ensures safety by preventing the arc from escaping.

Cradle: The cradle is the supporting frame that holds the circuit breaker in place within the panel or enclosure. It ensures secure mounting and alignment for proper operation.

Draw-out Handle: The draw-out handle allows for easy removal or insertion of the circuit breaker from its cradle. This facilitates maintenance and inspection without dismantling the entire system.

Position Indicator: The position indicator shows the physical position of the circuit breaker, whether it is fully inserted, withdrawn, or in a test position. It aids in ensuring correct placement during operation.

Handle Inserting Hole: The handle inserting hole is where the manual charging handle is inserted to charge the spring mechanism. It provides access for manual operation when needed.

Pad Lock Button: The pad lock button allows for locking the breaker in the off position using a padlock. This ensures that the breaker cannot be accidentally turned on during maintenance.

Arc Chute: The arc chute is the internal component that cools and extinguishes the electrical arc when the breaker operates. It contains metal plates that split and cool the arc quickly.

Front Cover: The front cover provides protection for the internal components of the circuit breaker. It also houses indicators and buttons, giving access to the controls while keeping the internals safe from dust and damage.

Also Read: Importance of Power Transmission Lines | Explained

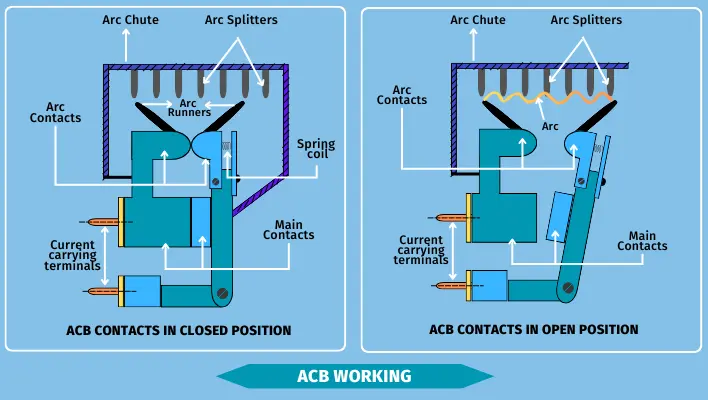

Air Circuit Breaker (ACB) Working

An Air Circuit Breaker working involves detecting faults, triggering a tripping mechanism that separates the contacts, managing and extinguishing the resulting arc, and providing visual feedback and safety features to ensure proper operation and maintenance.

Here’s a step-by-step explanation of Air Circuit Breaker working:

Closing Operation

When the breaker is closed, electricity flows through its main contacts. This is made possible by a part called the closing coil, which acts like a magnet. When it gets energized, it pulls an operating mechanism that shuts the main contacts, allowing current to pass through the circuit.

Tripping Operation

If something goes wrong, like an overload or a fault, the breaker steps in to stop the current. Protection devices inside the breaker, such as thermal overload relays or electronic relays, keep an eye on the current. If it gets too high, these devices send a signal to a part called the trip coil, which then breaks (trip) the circuit.

Arc Extinction

When the breaker opens to stop the current, a bright, hot arc forms between the contacts. This arc is essentially a small lightning bolt. To put out this arc, the breaker uses air at atmospheric pressure. The arc is guided into a part called the arc chute, which cools it down and breaks it apart until it goes out.

Arc Chutes

The arc chute’s basic role is to manage the arc effectively. It has several plates or fins that make the arc travel a longer, more complex path. This breaks the arc into smaller parts and helps to cool it down faster, making it easier to extinguish.

Managing Release of Energy

The arc quenching procedure leads to the release of energy which is managed carefully and is not allowed to escape the chute. This prevents any damage to the breaker’s components.

Contact Separation Completion

Once the arc is gone, the main contacts are fully separated. This stops the current completely and isolates the part of the circuit that had the problem.

Visual and Mechanical Indicators

ACBs have various indicators to show their status. These might include an ON/OFF indicator and a charge/discharge indicator. These indicators help you see whether the breaker is open or closed and if the spring mechanism is charged or not.

Resetting the Breaker

After fixing the fault and doing any needed maintenance, you can reset the breaker. This involves manually recharging the spring mechanism with a handle. Then, you press the ON button to close the contacts again, allowing electricity to flow through the circuit once more.

Also Read: Essential Guide to Voltage Unbalance

Air Circuit Breaker Types

Each Air circuit breaker type offers specific advantages and is chosen based on the application requirements, including current ratings, installation preferences, operational ease, and the level of protection needed.

On the Basis of Number of Poles

Air circuit breakers can be classified based on the number of poles, which are the separate paths for current within the breaker.

- Three-Pole (3P) ACBs: 3-pole ACBs provide protection for the three-phase conductors but do not protect the neutral conductor, making them suitable for systems without a neutral or where neutral protection is not critical.

- Four-Pole (4P) ACBs: These are ideal for applications where the neutral needs to be monitored and protected, such as in balanced and unbalanced load conditions.

On the Basis of Rated Current

ACBs are also categorized based on their rated current, which is the maximum continuous current they can handle without tripping.

- Low Current ACBs: Typically rated up to 630 A. Used in smaller installations.

- Medium Current ACBs: Rated between 630 A to 4000 A. Suitable for larger commercial and industrial applications.

- High Current ACBs: Rated above 4000 A. Used in heavy industrial and utility applications where high currents are common.

On the Basis of Installation Method

The installation method of ACBs can vary depending on the design and requirements of the electrical system.

- Fixed Type ACBs: Installed in a fixed position within the electrical panel. They are not meant to be easily removed or replaced without de-energizing the entire panel.

- Draw-out Type ACBs: It consists of two components: the main breaker unit and the panel board frame. The main breaker unit is attached to a draw-out frame that connects directly to the panel board. This design allows the main breaker unit to be removed from the panel board without shutting down the entire panel.

On the Basis of Spring Charging

Spring charging refers to the mechanism that closes and opens the breaker contacts.

- Manual Spring Charging: Manual Spring Charging involves manually winding or charging the spring mechanism using a handle or lever.

- Motorized Spring Charging: Motorized Spring Charging involves using an electric motor to charge the spring mechanism automatically.

On the Basis of Trip Mechanism

The trip mechanism is crucial for the operation of ACBs, as it determines how and when the breaker will trip to interrupt the current flow.

- Thermal-Magnetic Trip Mechanism: It has both thermal and magnetic elements. The thermal element protects against overloads by heating up and bending to trip the breaker, while the magnetic element quickly responds to short circuits at high speeds by creating a magnetic field that triggers the breaker.

- Electronic Trip Mechanism: Uses electronic sensors and microprocessors to detect over-currents and short circuits with high precision. These breakers offer adjustable settings and advanced protection features like ground fault protection.

- Microprocessor-Based Trip Mechanism: Similar to electronic trip mechanisms but with more advanced features and programmability. They provide very accurate and customizable protection settings and often include communication capabilities for integration into larger control systems.

Also Read: Power Supply System | A Comprehensive Guide

Selection Of Air Circuit Breaker

Choosing the right Air Circuit Breaker (ACB) for your electrical system involves looking at a few key factors. Here’s what you need to consider:

System Voltage

First, check the voltage of your electrical system. Make sure the ACB you select matches this voltage, whether it’s 230V, 415V, 690V, or another level.

Load / Current Rating

Next, determine the maximum current your circuit will handle. Choose an ACB that can support this continuous current without tripping.

Short Circuit Current Rating

Find out the highest current that could occur during a short circuit. Your ACB should have a rating higher than this to ensure it can safely interrupt the flow without damage.

Fault Level

Make sure the ACB can handle the maximum fault current it might face. This capacity should exceed any potential fault currents in your system.

Number of Poles

Decide how many separate circuits or phases you need to protect:

- Three-Pole (3P): For three-phase systems without a neutral.

- Four-Pole (4P): For three-phase systems with a neutral.

Type of Operation

Think about how the ACB will be charged and operated:

- Manual Spring Charging: Good for simple, cost-effective setups.

- Motorized Spring Charging: Best for remote control, frequent switching, and quick recharging.

Protection Features

Ensure the ACB has the protection features you need:

- Overload Protection: To handle sustained over-currents.

- Short Circuit Protection: To interrupt high fault currents.

- Ground Fault Protection: If needed for your application.

- Adjustable Settings: For precise and customizable protection.

Environmental Condition

Consider the conditions where the ACB will be installed:

- Ambient Temperature: Make sure the ACB works well in your temperature range.

- Altitude: You might need to derate the ACB if you’re at a high altitude.

- Humidity and Corrosion: Choose ACBs with the right coatings or enclosures if your environment is humid or corrosive.

Also Read: Discover the Top Earthing Essentials: Types, Parts & Purpose

Difference Between ACB and VCB

| Feature | Air Circuit Breaker (ACB) | Vacuum Circuit Breaker (VCB) |

| Voltage | Suitable for applications under 1000 volts, ideal for low voltage (LV) scenarios. | Suitable for medium voltage applications, up to 33 kV. |

| Working Principle | Operates by separating contacts in air, with air acting as the dielectric medium to quench the arc. | Utilizes vacuum as the medium to extinguish the arc, preventing free electron formation. |

| Medium Pressure | Relies on open-air pressure to extinguish the arc. | Maintains a vacuum pressure of 10-2 to 10-6 Torr to quench the arc. |

| Refilling | Does not require refilling as it uses ambient air. | Requires the replacement of the vacuum container if it fails. |

| Application | Commonly used in low tension Motor Control Centers (MCC), secondary circuits of Transformers, and Power Control Centers (PCC). Ideal for indoor use. | Used for starting high voltage motors and medium voltage substation applications. |

| Arc Chute and Arc Development | Uses arc chutes to break the arc into smaller parts. Arc development is significant. | Does not require arc chutes. Arc development is minimal due to the vacuum environment. |

| Safety | Moderate safety with a higher risk of arc flash incidents. | Higher safety with reduced risk of arc flash incidents |

| Cost | Generally more cost-effective for low voltage applications. | Higher initial cost but more efficient for medium voltage applications. |

ACB FAQs

What is the difference between an Air Circuit Breaker and other types of circuit breakers?

The main differences between ACBs and other circuit breakers, such as SF6, vacuum, and oil circuit breakers, lie in the medium used for arc extinction, the interrupting capacity, size, weight, and application suitability. Each type has its own advantages and is selected based on specific needs and conditions of the electrical system.

Can Air Circuit Breakers be used for both AC and DC applications?

While ACBs are primarily designed for AC applications, some models can be used for DC applications with appropriate modifications for up-to 1600V DC. It’s important to consult the manufacturer’s specifications to ensure compatibility.

Where are Air Circuit Breakers commonly used?

ACBs are commonly used in industrial plants, commercial buildings, and power distribution systems where high voltage and high current levels are present. They are particularly used in low voltage applications (below 1000V).

Can Air Circuit Breakers be remotely operated or monitored?

Yes, modern ACBs feature remote operation capabilities and monitoring systems that enable real-time status monitoring, fault diagnostics, and control from a central location.

What types of faults can an Air Circuit Breaker protect against?

ACBs protect against various types of faults, including:

Overcurrent: Excessive current flow that exceeds the circuit’s capacity.

Short Circuit: Direct connection between live conductors, causing a large current flow.

Earth Fault: Leakage of current to the ground.

Overvoltage: Voltage higher than the normal operating level.