The given question was featured in the 2019 Energy Manager Examination Paper 3.

Numerical Problem

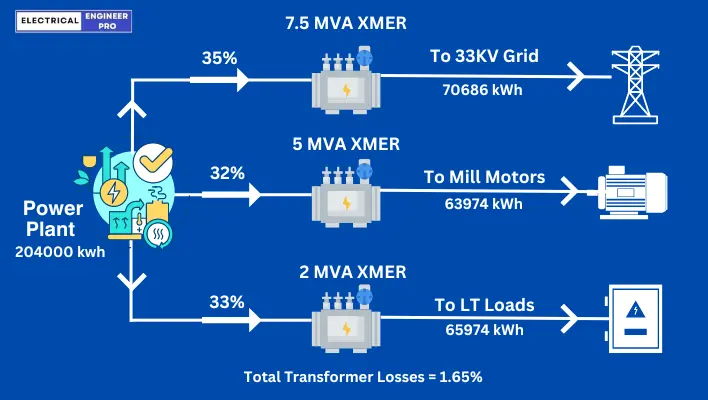

A 10 MW co-generation plant is operating at a daily load factor of 85 %. Power is generated at 11 KV.

- 35 % of the power generated, is exported to the grid, through a 7.5 MVA Transformer with 99 % efficiency.

- 32 % power generated, is supplied to mill motors, at 600 Volts, through a 5 MVA step down transformer, with 98 % efficiency.

- The balance power generated is supplied to other LT Loads and auxiliaries, at 415 Volts, through a 2 MVA transformer, with 98 % efficiency.

Calculate the following:

- Daily energy exported to the grid at 33 KV.

- Daily mill motors consumption at 600 V.

- Daily LT loads and auxiliary consumption at 415 V.

- Daily transformers losses in kWh and % transformers losses

Given Data

| Load Factor of 10 MW power generation plant. | 85% |

| Percentage of power exported to the grid. | 35% through 7.5 MVA Transformer @ 99 % efficiency. |

| Percentage of power supplied to mill motors. | 32% through 5 MVA Transformer @ 98 % efficiency. |

| Balance Power supplied to LT Loads and auxiliaries. | 100 – (35 + 32) = 33% through 2 MVA @ 98 % efficiency |

Solution

To calculate the following, first we need to find the total daily power generated by the 10 MW co-generation power plant.

- Daily Power generation of co-generation plant.

- Daily energy exported to the grid at 33 KV.

- Daily mill motors consumption at 600 V.

- Daily LT loads and auxiliary consumption at 415 V.

- Daily transformers losses in kWh and % transformers losses.

Also Read: Calculate motor temperature rise from unbalanced voltage | Energy Manager Exam question

Total Daily Power Generation by Co-generation plant.

| Daily Generation | = Power Plant Capacity (KW) X Load Factor X 24 (Total hours in day) |

| = (10 x 1000)(0.85)(24) {Multiplied by 1000 to convert MW to KW} | |

| = 204000 kWh |

Useful to know

In electrical engineering, the term “load factor” refers to the ratio of the actual power consumed by a device, system or electrical equipment to the maximum power it could consume under continuous full-load operation.

[latex]Load Factor = \frac{Average Power}{Maximum Power}[/latex]

The load factor is used to evaluate the efficiency and utilization of electrical equipment, especially in power systems. It gives an indication of how effectively the electrical system or device is utilizing the available power capacity.

A load factor close to 1 (or 100%) indicates that the equipment is operating at or near its full capacity most of the time, resulting in efficient utilization of the available power.

On the other hand, a load factor closer to 0 (or 0%) indicates that the equipment is not utilizing its full capacity efficiently and may have idle or underutilized periods.

Daily energy exported to the grid at 33 KV

| It is given that 35 % of the power generated, is exported to the grid, through a 7.5 MVA Transformer with 99 % efficiency. | ||

| 1 | Daily generation for export purpose. | = (Daily Power Generated) X 0.35 |

| = 204000 kWh X 0.35 | ||

| = 71400 kWh | ||

| 2 | But power is exported through 7.5 MVA transformer having 99% efficiency. | |

| Therefore, transformer loss. | = 71400 – (71400 X 0.99) | |

| = 714 kWh | ||

| 3 | Net energy exported to the grid at 33KV. | = 71400 – 714 |

| = 70686 kWh |

Useful to Know

A co-generation power plant, also known as a combined heat and power (CHP) plant, is a type of power generation facility that simultaneously produces electricity and useful heat or steam for industrial, commercial, or residential purposes. It is a highly efficient approach to energy production because it captures and utilizes waste heat that would otherwise be wasted in conventional power plants.

Daily mill motors consumption at 600 V

| It is given that 32 % power generated, is supplied to mill motors, at 600 Volts, through a 5 MVA step down transformer, with 98 % efficiency. | ||

| 1 | Daily generation to supply power to Mill Motors . | = (Daily Power Generated) X 0.32 |

| = 204000 kWh X 0.32 | ||

| = 65280 kWh | ||

| 2 | But power is supplied through 5 MVA transformer having 98% efficiency. | |

| Therefore, transformer loss. | = 65280 – (65280 X 0.98) | |

| = 1306 kWh | ||

| 3 | Net energy supplied to mill motors. | = 65280 – 1306 |

| = 63974 kWh |

Daily LT loads and auxiliary consumption at 415 V

| It is given that the balance power generated is supplied to other LT Loads and auxiliaries, at 415 Volts, through a 2 MVA transformer, with 98 % efficiency. | ||

| 1 | Daily generation to supply power to LT loads. | = 100 – (0.35 + 0.32) = 100 – 0.67 = 0.33 |

| Hence, | = 204000 kWh X 0.33 | |

| = 67320 kWh | ||

| 2 | But power is supplied through 2 MVA transformer having 98% efficiency. | |

| Therefore, transformer loss. | = 67320 – (67320 X 0.98) | |

| = 1346 kWh | ||

| 3 | Net energy supplied to LT loads. | = 67320 – 1346 |

| = 65974 kWh |

Useful to Know

Electrical transformer efficiency refers to the ratio of output power (useful power delivered to the load) to input power (power supplied to the transformer). It measures how effectively the transformer converts electrical power from one voltage level to another with minimal energy losses.

The efficiency of a transformer is denoted as a percentage and can be calculated using the following formula:

[latex]Efficiency\% = \frac{Output Power}{Input Power}\times100[/latex]

Transformer efficiency is affected by two main types of losses:

- Copper Losses (I2R Losses)

- Iron Core Losses (Eddy Current and Hysteresis Losses)

Daily transformers losses in kWh and % transformers losses

| 1 | Total Transformer losses. | = 714 + 1306 +1346 |

| = 3366 kWh/day | ||

| 2 | % Transformer loss | = (3366 / 204000) X 100 |

| = 1.65% |

Summary

| 1 | Daily Power generation of co-generation plant. | 204000 kWh |

| 2 | Daily energy exported to the grid at 33 KV. | 70686 kWh |

| 3 | Daily mill motors consumption at 600 V. | 63974 kWh |

| 4 | Daily LT loads and auxiliary consumption at 415 V. | 65974 kWh |

| 5 | Daily transformers losses in kWh | 3366 kWh/day |

| 6 | % Transformers losses. | 1.65% |

Also Read: How to find 3-phase AC motor parameters? Energy Manager exam question.