Power plants are the backbone of our modern society, providing the energy we need to power our homes, businesses, and technology. But did you know that not all power plants are created equal? There are various types of power plants, each with its unique set of functions and advantages. From traditional fossil fuel plants to innovative renewable energy sources, understanding the different types of power plants is essential for our energy future.

In this article, we’ll take a closer look at some of the most common types of power plants, exploring how they work, their environmental impact, and their potential for sustainable energy production. Whether you’re an energy enthusiast or simply curious about the world around you, this guide will provide you with a comprehensive overview of the fascinating world of power plants. So, let’s dive in and discover the many different types of power plants and their functions!

Also Read: Power Supply System | A Comprehensive Guide

What is a Power Plant?

A power plant is an assembly of electrical equipment working together to generate and deliver both mechanical and electrical energy. It has things like generators, transformers, switchgears, and control gears all working in sync to produce power.

Power plants are also called Power stations or Power Generation Facilities.

The main job of Power Plants is to produce electrical energy using different sources. They take energy from things like chemicals, nuclear reactions, or mechanical processes and turn it into electricity that we can use for all sorts of things.

These power plants are super important because they’re the ones responsible for supplying electricity to our homes, businesses, and industries.

They’re massive installations with all kinds of machinery and systems that are specifically designed to generate electricity in the most efficient and reliable way possible.

You’ll usually find power plants located near energy sources or places where there’s a high demand for electricity. It requires a whole lot of planning, engineering, and maintenance to make sure they operate safely and reliably.

Once they generate electricity, it gets sent through power grids and distributed to all of us consumers, whether we’re using it in our homes, businesses, or industries.

Also Read: Importance of Power Transmission Lines | Explained

Components of power plant

Power plants can vary in terms of their components depending on the type of primary source they use to generate power.

Whether a power plant is coal-fired, gas-fired, nuclear, hydroelectric or renewable, may have additional specialized components based on its specific technology and requirements.

However, there are certain parts that you’ll find in pretty much every power plant.

Let me walk you through some of the main components you can expect to find in a typical power plant.

- Boiler: The boiler is responsible for converting water into steam by using heat from the combustion of fuel. The steam produced in the boiler is used to drive the turbine.

- Turbine: The turbine is a large machine with blades that spin when high-pressure steam flows through them. The spinning motion of the turbine converts the steam’s energy into mechanical energy.

- Generator: The generator is connected to the turbine and converts the mechanical energy from the turbine into electrical energy. It contains coils of wire that rotate within a magnetic field, creating an electric current.

- Condenser: Once the steam has gone through the turbine, it undergoes cooling and condensation in the condenser, transforming back into water. This crucial step enables the reuse of the steam in the boiler, leading to enhanced overall efficiency.

- Cooling System: Power plants need a cooling system to adjust the temperature of different parts. Common cooling methods include the use of cooling towers, water from nearby rivers or lakes, or air-cooled systems.

- Fuel Storage: Power plants require a storage area for the fuel they use, such as coal, natural gas, oil, or nuclear fuel. These fuels are stored in designated areas on-site and are transported to the boiler for combustion.

- Control Room: The control room is the center of the power plant. It houses the control systems and monitors that allow operators to manage and regulate the plant’s operations, including adjusting fuel supply, monitoring temperature and pressure, and ensuring safety.

- Transformers and Switchgear: Transformers are used to step up or step down the voltage of the electricity generated in the power plant for transmission or distribution. Switchgear is responsible for controlling and protecting electrical circuits within the plant.

Types of power plants

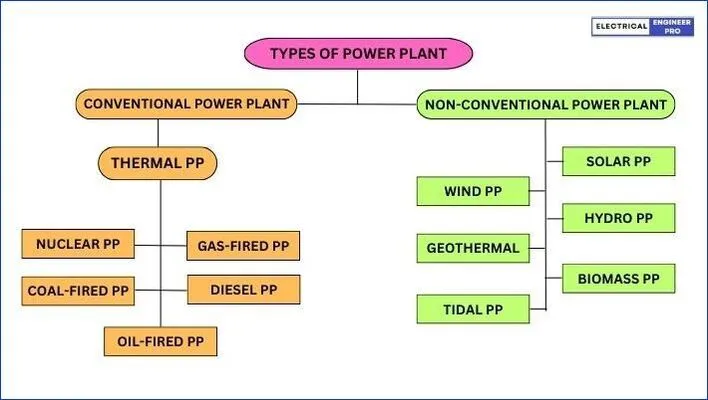

Power plants can be classified in different ways.

They can be grouped based on factors like the type of load they handle, whether it’s a Base Load or Peak Load plant.

They can also be categorized by their location, whether they’re centralized or isolated.

Another way to classify them is by mobility, distinguishing between mobile and stationary plants.

However, in today’s energy landscape, it’s more relevant to classify power plants based on their primary fuel source, specifically whether they’re conventional or non-conventional.

Conventional power plants are the ones that rely on non-renewable sources such as coal, oil, and natural gas to generate power. These sources are limited and can’t be quickly regenerated once they’re used up.

On the other hand, non-conventional power plants make use of renewable natural sources like the sun, wind, rain, tides, and vegetation for power generation. Renewable natural resources can be replenished within a reasonable time frame after being utilized.

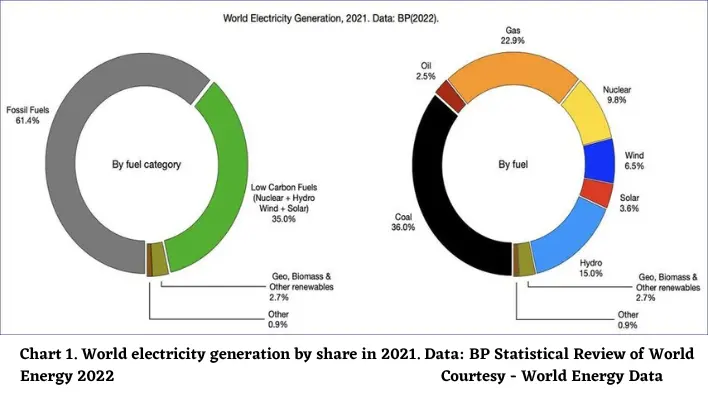

Nearly 90% of the world’s power is generated from Conventional power plants so only those are discussed below,

Also Read: What is interconnected power system or grid?

Thermal Power Plants

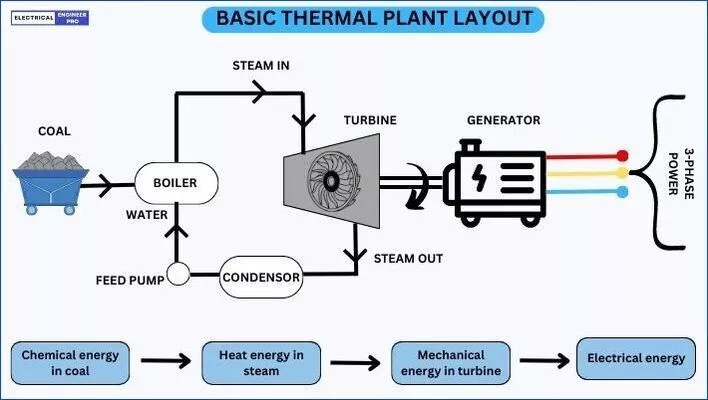

Thermal power plants are a type of power plant that generates electricity by using heat energy. They rely on burning fossil fuels like coal, oil, or natural gas to create the heat they need.

The burning fuels produce a lot of heat, and that heat is used to make steam in a boiler.

Once the steam is created, it’s under high pressure and temperature, and it’s sent to a turbine.

As the high-pressure steam passes through the blades of the turbine, it undergoes a transformation from thermal energy to mechanical energy, initiating the rotation of the turbine.

It’s this rotational movement that powers a generator and converts the mechanical energy into electrical energy.

So, in a thermal power plant, you have this whole process going on.

Once the electricity is produced, it’s sent through power grids and distributed to homes, businesses, and industries, so we can use it for all sorts of things.

Thermal power plants are popular worldwide because they provide a reliable and steady supply of electricity. However, they do come with some environmental concerns.

The burning of fossil fuels releases greenhouse gases and pollutants into the air, which contribute to climate change and air pollution. That’s why there’s a big push to develop cleaner and more sustainable alternatives in the field of power generation.

The Steam Power Plant, Diesel Power Plant, Gas Turbine Power Plant, and Nuclear Power Plant are collectively known as Thermal Power Plants. This classification is due to their ability to convert heat into electrical energy.

Types of Thermal power plants based on primary fuels.

Coal Fired

Coal is a predominant fuel in electricity generation worldwide. Coal-fired power plants produce nearly 36% of the global electricity.

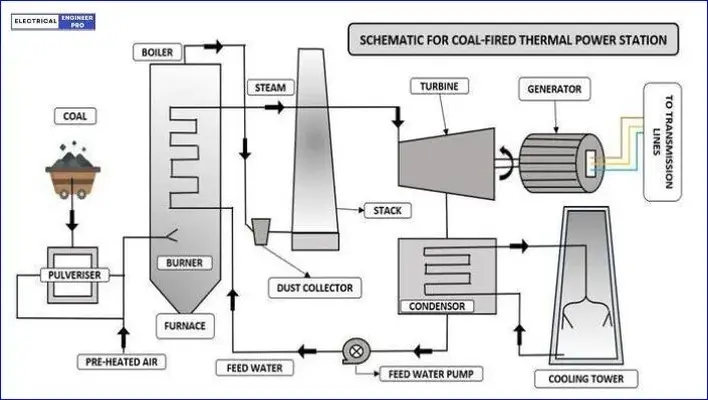

A coal-fired power plant typically consists of several components, including a boiler, turbine, generator and various auxiliary systems.

At the start of the process the dense coal is crushed into super fine particles. This finely powdered coal is then mixed with hot air inside the boiler.

The goal here is to create a perfect blend of coal and air, which results in a powerful combustion, producing the highest amount of heat possible.

At the same time, water is pumped into the boiler and heated up real nice. The heat turns that water into steam.

The steam produced has a scorching temperature of up to 1000 degrees Fahrenheit and has an intense pressure of 3500 pounds per square inch.

The super pressurized steam is directed towards the turbine blades, which in turn spins the turbine shaft.

The turbine shaft is connected to the shaft of the generator which generates electricity through the principle of electromagnetic induction.

Coal is the most disadvantageous fuel between oil and natural gas because of its high calorific value.

It produces a range of harmful substances, such as carbon dioxide (CO2), sulfur dioxide (SO2), nitrogen oxides (NOx), and particulate matter. These emissions have negative impacts on air quality, contribute to climate change and pose health risks.

Another unfavorable part of coal fired power plants is that their maximum efficiency is up to 30% to 40% because of the heat losses in the condenser and also at various stages of the plant.

This means that 60% of the energy input to the system is wasted. Efficiencies can be as low as 30% in some older plants.

Also Read: Smart Grid | The Ultimate Guide

Gas fired

Natural gas is a natural blend of hydrocarbon gases, mostly made up of methane. It may also contain varying levels of alkanes, as well as traces of carbon dioxide, nitrogen, hydrogen sulfide or helium.

Similar to coal-fired power plants, gas-fired power plants consist of various components and systems that work together to generate electricity efficiently.

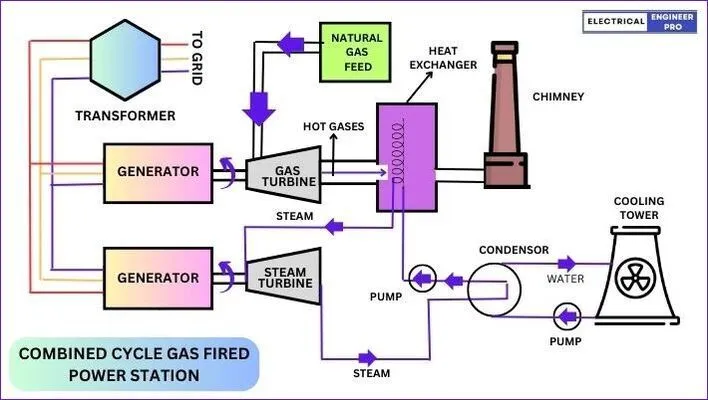

Gas power plants come in two types: simple cycle and combined cycle.

In simple cycle plants, It’s a straightforward process, the hot gas is propelled through turbine blades to create electricity.

However, to improve the thermal efficiency of gas plants, a combined-cycle approach is employed.

In this method, power is generated in two phases. First, gas turbine engines connected to electric generators produce electricity.

Then, the hot gases expelled from the gas turbines pass through a heat exchanger to create steam. This steam is then utilized to operate a traditional steam generator, which produces electrical energy.

Then again, the hot gases expelled from the gas turbine can be utilized to generate steam for industrial processes.

Gas-fired power plants offer the advantage of higher efficiency compared to coal-fired plants, with the ability to achieve efficiencies of approximately 50% or even higher.

Furthermore, these power plants generate lower emissions when compared to coal, resulting in reduced levels of pollutants like sulfur dioxide (SO2) and particulate matter.

Though considered more environmentally friendly than coal fired power plants, they still contribute to carbon dioxide (CO2) emissions.

Oil fired

In the oil fired steam station, oil is put to use to make steam, which is used to run the steam turbine.

In most gulf countries crude oil is used as it is easily available and can be directly pumped from the oil wells. Even the residue extracted from crude oil is utilized for generating power.

High viscosity in residue oil makes it quite costly to transport, so this type of oil fired stations are near oil refineries.

Oil, being highly convenient, used to be the preferred fuel choice. However, due to the rapid increase in oil prices, coal has largely taken over as a more cost-effective alternative.

Diesel oil fired

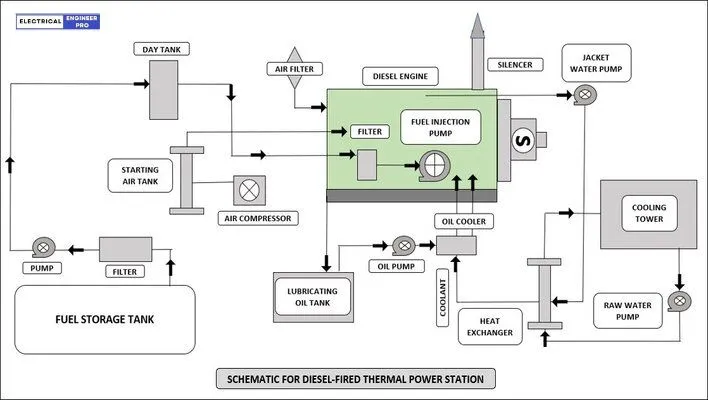

Diesel oil is the primary fuel used in large internal combustion engines of heavy-duty vehicles.

The diesel oil fired stations and oil fired stations share the same qualities but the speed of the diesel fired station is relatively low and its efficiency is higher than steam engines.

The diesel engine drives an alternator which converts mechanical energy into electrical energy.

As diesel is more costly than oil or any other fossil fuel, its uses are limited only supplying back-up power.

Nuclear Power Plant

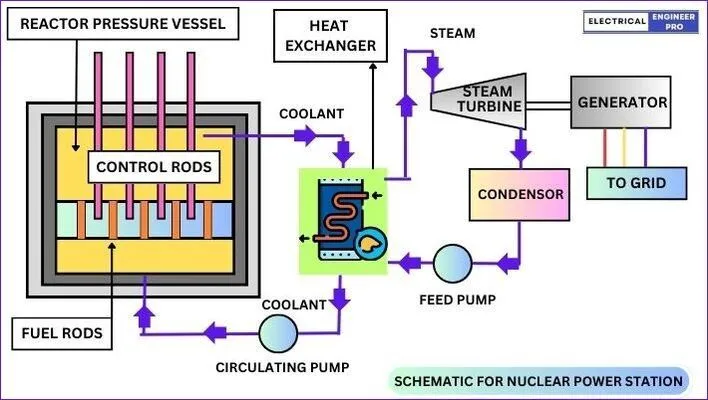

The nuclear power generating stations are almost like thermal stations.

However, the difference here is that radioactive elements like Uranium and thorium are used as primary fuel instead of coal.

Besides the fuel, the nuclear power plant has a nuclear reactor instead of a boiler and furnace.

The naturally obtained uranium comprises 0.7% of 235U. 99% of 238U and 0.05% of 234U. To fabricate the uranium as a worthy fuel. It is put through a gas diffusion process and the concentration of component 235U is increased by 90%.

In the nuclear reactor the enriched 235U is bombarded with neutrons which results in a lot of heat energy and additional neutrons. These added neutrons are further bombarded with 235U to produce more and more neutrons.

Thus in the nuclear reactor a chain reaction is set up. A moderator and control rods are used to ensure a sustainable chain reaction.

A primary coolant such as liquid sodium or some gaseous fluids is used to transfer the heat generated because of the fission reaction to the heat exchanger. The steam generated in the heat exchanger is utilized to operate a traditional steam turbine.

One notable characteristic of nuclear power plants is their high energy density. A small amount of nuclear fuel can generate a substantial amount of electricity. This makes nuclear power a reliable and efficient source of energy.

The fission of 1 g of uranium or plutonium per day liberates about 1 MW. This is the energy equivalent of 3 tons of coal or about 600 gallons of fuel oil per day, which when burned produces approximately 1/4 tonne of carbon dioxide.

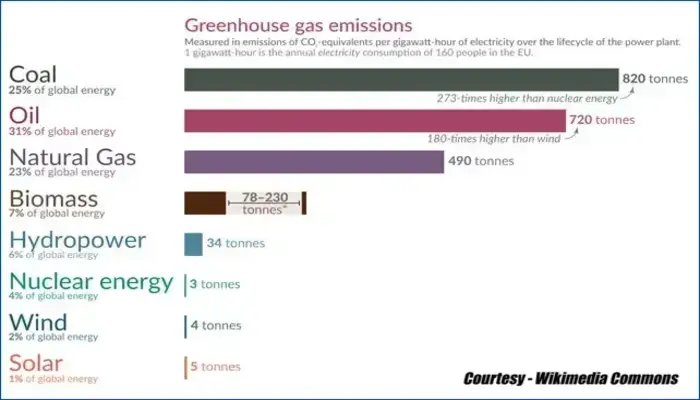

Additionally, nuclear power plants produce electricity without emitting large quantities of greenhouse gases, such as carbon dioxide, which contribute to climate change.

However, nuclear power plants do produce radioactive waste, which requires careful management and disposal to ensure its safe handling and minimize environmental impact.

Despite the advantages of nuclear power, concerns about nuclear accidents, nuclear waste disposal, and the potential for misuse of nuclear materials exist.

These factors contribute to ongoing debates surrounding the use of nuclear power as a part of the energy mix in various countries.

Also Read: Types of High Voltage Circuit Breakers | Explained

What are the impacts of power plant construction and operation?

Power plants, both during their construction and operation, can have various effects on the environment. These effects can be temporary or permanent, and they include factors such as land use, resource consumption, pollutant emissions, and waste management.

- Land Use and Visual Effects

Power plants and their associated parts take up a lot of space on the ground and in the air. This means that there is less room for other purposes, and it can affect the way nearby land is used.

For example, tall buildings and exhaust stacks in coal-fired plants can be a problem for aeroplanes and can also change the way the area looks for people who live nearby.

If a power plant is built on land that hasn’t been developed before, it can have an impact on the way the land is used, the quality of the soil and the animals and plants that live there.

- Pollutant Emissions and Air Quality

Different kinds of power plants produce electricity in different ways. Some burn fuels like fossil fuels and biomass, while others use nuclear reactions. When these fuels are burned or nuclear reactions occur, they create exhaust gases and other substances that can pollute the air.

Also making steam to generate electricity requires a lot of water. This water is often taken from nearby sources like rivers, lakes, or underground reservoirs.

Before it’s used, the water has to be cleaned. In some cases, water used in the power plant needs to be discharged after use, and factors such as the amount, temperature, and pollutant concentration of the discharged water must be considered.

- Water Consumption and Discharge

Power plants rely on water for cooling, and this water is often passed through cooling towers to reduce heat. As a result, large quantities of water vapour are released into the atmosphere. This represents a significant water consumption by the power plant, as millions of gallons of water can be lost each day.

- Solid Waste Management

The operation of power plants produces various solid wastes that need to be properly handled. Coal combustion creates ash as a solid waste, while nuclear power plants generate spent fuel rods and low-level radioactive waste. Power plants using water for steam generation or cooling often need to filter and purify the water before discharging it into surface waters, resulting in filtered solids that require appropriate disposal.

- Community Concerns and Disruptions

Power plant construction and operation can negatively impact the local community. The construction process can be seen as chaotic and unattractive, affecting the community’s appearance and businesses.

It can also lead to increased costs for essential services like police, fire protection, and emergency medical services. Additional demands may be placed on water supply, wastewater treatment, and waste management.

Efficient coal delivery can disrupt local traffic, and construction activities create noise and vibration. The cooling towers of operational plants can generate fog and ice. Airspace and compatibility with land use must be considered to minimize these effects.

- Positive Effects on the Community

Power plants can have positive effects on the community. They create job opportunities for local residents and support the local economy by purchasing goods and services from the area. This generates additional income streams and increases tax revenue for local municipalities. Moreover, the electricity generated by the power plant can replace the need for purchasing power from other states, which can have fluctuating and unreliable prices. The operation of the plant also helps stabilize the local electric transmission grid, ensuring efficient and reliable power distribution.

What are the methods used to reduce pollution in Power Plants?

Conventional fossil fuel power plants are responsible for 87% of the global CO2 emissions. A world heavily reliant on fossil fuels is not sustainable as it poses a threat to the well-being and future prospects of upcoming generations and the biosphere that surrounds us.

Power plants employ various methods to reduce air pollution emissions and meet air pollution emission standards. Here are some ways in which power plants address these concerns:

- Burning low-sulfur-content coal

Power plants can reduce sulfur dioxide (SO2) emissions by using coal with a lower sulfur content. This approach involves sourcing coal that naturally contains lower levels of sulfur. Additionally, some coal-fired power plants practice co-firing, where they burn a combination of wood chips and coal. This mixture helps lower SO2 emissions.

- Pretreatment and processing of coal

Power plants can subject coal to pretreatment and processing techniques to reduce the presence of undesirable compounds in combustion gases. By treating coal before combustion, power plants can minimize the emission of pollutants during the burning process.

- Particulate emission control devices

Power plants utilize different types of devices to treat combustion gases and reduce particulate matter emissions. These devices include:

Baghouses: These are large filters that trap particulate matter, preventing it from being released into the atmosphere.

Electrostatic precipitators: Using electrically charged plates, these devices attract and remove particulate matter from the combustion gas stream.

Wet scrubbers: Wet scrubbers employ a liquid solution to eliminate particulate matter from the combustion gas. The solution captures the particulates, allowing cleaner gases to be emitted.

- Scrubbers for SO2 emissions

To address SO2 emissions, power plants employ wet and dry scrubbing methods.

In wet scrubbers, lime is either mixed with the fuel (coal) or a lime solution is sprayed into the combustion gases. The lime reacts with the SO2, resulting in reduced emissions. Dry scrubbers also use lime or other sorbent materials to capture and remove SO2 from the combustion gas stream. Additionally, fluidized bed combustion technology helps lower SO2 emissions.

- NOx emissions controls

Power plants employ various techniques to control nitrogen oxide (NOx) emissions

Low NOx burners: These burners are specifically designed to reduce the formation of NOx during combustion by creating an environment with reduced oxygen and temperature levels.

Selective catalytic converters and non-catalytic converters: These devices are used during the post-combustion phase to reduce NOx emissions. They employ catalysts or other chemical reactions to convert NOx into less harmful nitrogen and oxygen compounds.

These approaches and technologies help power plants meet air pollution emission standards and reduce their impact on air quality. By implementing these measures, power plants can contribute to improved environmental conditions and public health.

Conclusion

In conclusion, understanding the different types of power plants is essential for our energy future. From traditional fossil fuel plants to innovative renewable energy sources, each type of power plant has its unique set of functions and advantages. While fossil fuel power plants remain a crucial source of energy, there is a growing push towards cleaner energy sources, such as renewable energy. The future of power plants and renewable energy is one of innovation and progress, with the potential to transform the way we generate and use energy.