AC motor, short for Alternating Current motors, are essential components in a wide array of applications, from industrial machinery to household devices. In this blog post, we will delve into the world of AC motors, exploring their construction, various types, working principles, advantages and diverse applications.

What is AC Motor ?

In AC, the flow of electric charge reverses direction periodically, typically in a sinusoidal (wave-like) pattern. This alternating nature of the current is in contrast to Direct Current (DC), where the electric charge flows continuously in one direction.

AC motors operate using alternating current (AC), characterized by periodic changes in direction and magnitude over time. These motors convert electrical energy into mechanical energy by using single phase, two phase or three phases of power and are classified accordingly.

Also Read: Explore the Diverse World of DC Motors

Working principle of AC Motor

The fundamental idea behind the operation of an AC (alternating current) motor is electromagnetic induction. AC motors rely on the interaction between magnetic fields and conductors carrying alternating current to generate mechanical motion. Here’s a simple explanation of how this concept works:

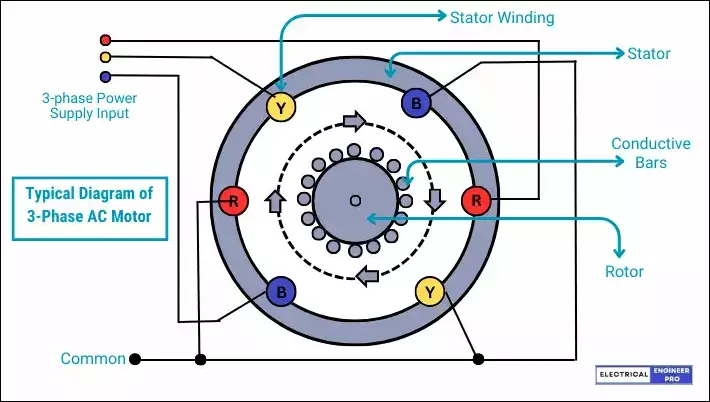

- Stator and Rotor: AC motors consist of two main parts: the stator and the rotor. The stator is the stationary part of the motor, typically made up of coils or windings of insulated wire arranged in a definite configuration. On the other hand, the rotor is responsible for rotation and is usually positioned inside the stator.

- AC Power Supply: When you connect the AC motor to an alternating current power source, such as the electrical outlet in your home or an industrial power grid, the voltage supplied alternates direction regularly, typically at a specific frequency (e.g.60 Hz or 50 Hz).

- Creation of Rotating Magnetic Field: When you connect AC voltage to the stator’s coils, it creates a magnetic field that synchronously reverses its direction in line with the alternating current. This changing magnetic field induces a rotating magnetic field around the coils. The key point is that the magnetic field in the stator constantly changes direction due to the alternating current.

- Induction in the Rotor: The rotor, which is located within the stator, is typically made of a series of conductive bars or loops. When the rotating magnetic field from the stator interacts with the rotor, it induces an electrical current in the rotor. This induced current generates its own magnetic field within the rotor.

- Rotational Force: Based on the laws of electromagnetism, the magnetic field of the rotor interacts with the rotating magnetic field of the stator, resulting in a force that either pushes or pulls the rotor. The specific direction of this force is determined by the corresponding orientations of the magnetic fields. As the stator’s magnetic field continues to change direction with the alternating current, it continually induces a current in the rotor, which in turn generates a rotating magnetic field and mechanical rotation of the rotor.

In summary, the basic principle of an AC motor’s operation involves the creation of a rotating magnetic field in the stator through the use of alternating current. This rotating magnetic field triggers electrical currents within the rotor, and as a consequence, the rotor generates its magnetic field, leading to the creation of mechanical rotation. The continuous change in the direction of the stator’s magnetic field results in the rotor’s continuous rotation, allowing the motor to perform various tasks and drive mechanical systems.

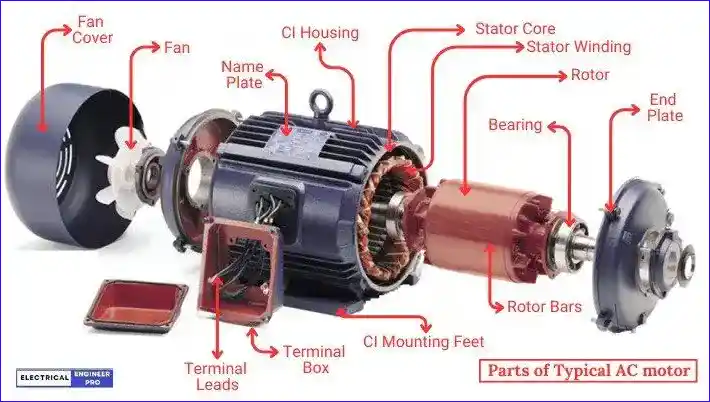

Parts & Construction of AC motor

Stator – The stator in an AC motor serves as the stationary part that generates a rotating magnetic field when it receives AC voltage. This magnetic field then engages with the rotor to generate the mechanical motion required for a variety of tasks and to power machinery. The stator’s capacity to produce a rotating magnetic field is crucial for the proper functioning of AC motors.

Stator Core – The core is typically made of laminated iron sheets that are stacked together to reduce energy losses due to eddy currents and to enhance the magnetic properties. It provides a path for the magnetic flux generated by the stator windings.

Stator Windings – Coils of insulated wire are wound around the stator’s core. These windings are connected to an AC power supply, and when AC voltage is applied, they carry alternating current. The current flowing through these windings generates a magnetic field around them. The design and configuration of these windings play a significant role in determining the motor’s performance characteristics, making them a critical aspect of motor design and engineering.

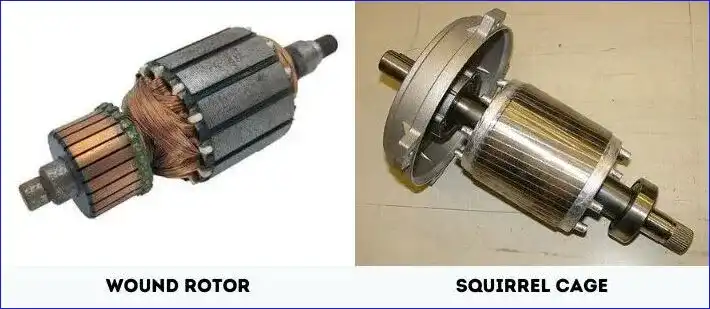

Rotor – The rotor in an AC motor is the moving part that rotates in response to the rotating magnetic field generated by the stator. It is responsible for converting the electrical energy from the stator into mechanical motion.

The rotor is constructed using punched laminations that are precisely stacked to form a sequence of rotor slots, creating room for the rotor winding. The choice of winding design leads to the classification of two primary motor types: squirrel cage induction motors and wound-rotor induction motors.

Rotor Bars – Rotor bars or rotor conductors are conductive elements within the rotor of an AC motor, responsible for conducting induced electrical currents and generating the torque required for the motor to operate. Their design and material selection are critical factors in determining the motor’s performance and efficiency.

Bearings – In a motor, bearings are essential components that provide support and allow for the smooth rotation of the motor’s moving parts, particularly the rotor. Bearings reduce friction, support the weight of the rotor and other components and help maintain the motor’s alignment.

Terminal Box – Terminal box in a motor plays a crucial role in the electrical connectivity and protection of the motor’s internal components. It ensures that electrical connections are secure, insulated and well-organized, facilitating safe and reliable motor operation while also simplifying installation and maintenance processes.

Inside the terminal box, you will find terminal leads or connectors to which the motor’s electrical conductors are connected. These terminals often consist of screws, studs, or other types of connectors designed to securely fasten and maintain electrical connections.

Housing Or Enclosure – The enclosure of a motor refers to the protective housing or casing that surrounds the internal components of the motor. The enclosure serves several important functions, including providing protection for the motor’s internal parts, ensuring safety, and managing environmental factors. The choice of motor enclosure depends on the specific application and environmental conditions in which the motor will operate.

Fan – In some motor designs, a fan is mounted on the motor shaft to help cool the motor during operation. This is common in TEFC (Totally Enclosed Fan Cooled) motors.

Shaft – The motor’s shaft is connected to the rotor and extends outside the motor housing. It’s used to transmit mechanical power to external equipment.

End plates – End covers or plates at the ends of the motor that help secure the rotor and stator in place. They also provide protection.

Nameplate – A nameplate is usually attached to the motor and provides important information such as the motor’s specifications, voltage rating, current rating, speed, and more.

Also Read: Electrical Machines | Discover the Basics

Electric Motor Types

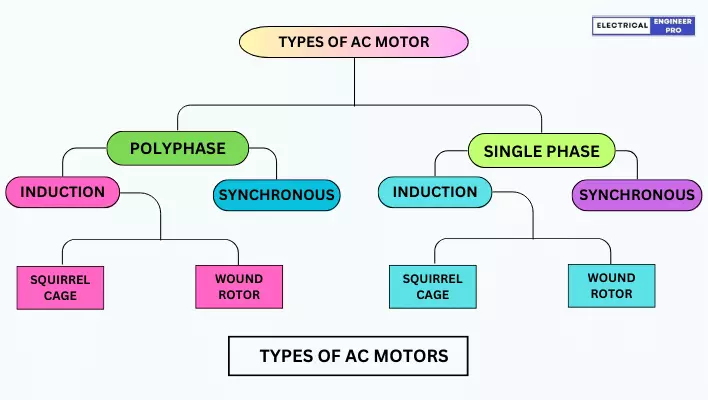

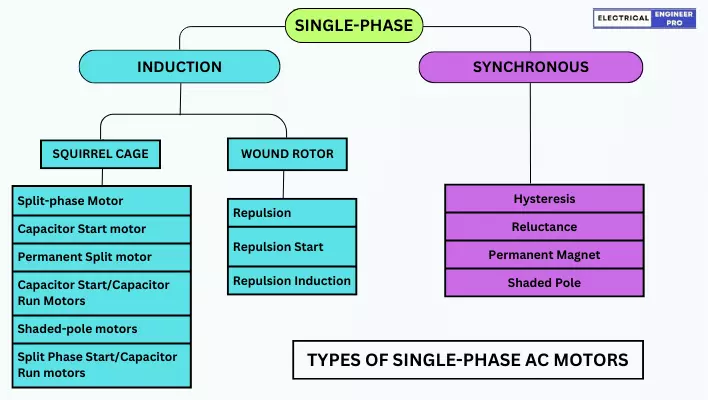

Electric motor types are categorized into two main groups: Poly-phase and Single phase motors. These categories are further divided into two based on their operating principle: Induction motors and Synchronous motors.

Induction Motors

Induction motors are a common category of AC motors known for their asynchronous operation. They derive their name from the induction of rotor currents by alternating currents in the stator windings. There are two principal types of induction motors: single-phase and poly-phase, each with unique characteristics.

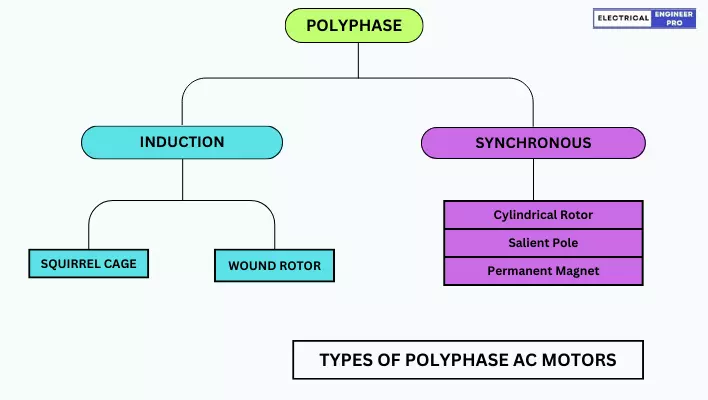

Poly-phase Induction Motors

Poly-phase induction motors are robust and efficient devices that operate on multi-phase AC power supplies, often three-phase configurations. They can be further categorized into two primary types based on rotor construction:

- Squirrel-Cage Induction Motors:

- These motors feature a rotor with shorted conductive bars, resembling a squirrel cage.

- Recognized for their simplicity, durability, and extensive use in various industrial applications.

- Ideal for tasks demanding reliable and robust performance.

- Wound-Rotor Induction Motors:

- In these motors, the rotor comprises windings connected to external terminals.

- External resistance adjustments enable precise control of motor speed and torque.

- Applied in scenarios necessitating variable speed control and enhanced motor performance.

Poly-phase induction motors, whether squirrel-cage or wound-rotor, function based on the same underlying physical principles. They use the interaction between rotor currents and the electromagnetic field in the air gap between the stator and rotor to generate mechanical torque.

These motors can be likened to AC transformers, featuring stationary primary windings in the stator and rotating secondary windings in the rotor. However, unlike transformers that facilitate electrical transformation, induction motors produce mechanical motion as a result of this interaction between rotor currents and the electromagnetic field.

Single-Phase Induction Motors

Single-phase induction motors are another category of AC motors designed for operation on single-phase AC power supplies. These motors are versatile and widely used in various applications.

Single-phase induction motors often require additional components and special starting methods. They are further classified according to these starting methods, which are,

Squirrel Cage Type Motor

- Split-phase Motor

- Capacitor Start motor

- Permanent Split motor

- Capacitor Start/Capacitor Run Motors

- Shaded-pole motors

- Split Phase Start/Capacitor Run motors

Wound Rotor Type Motor

- Repulsion

- Repulsion Start

- Repulsion Induction

In conclusion, induction motors are versatile devices known for their asynchronous operation, and they are categorized into two main types: poly-phase motors and single-phase motors, each serving distinct purposes in various applications.

Synchronous Motors

Synchronous motors are a type of AC motor known for their constant-speed operation, where they run in perfect synchronism with the AC line frequency. This characteristic sets them apart from other types of motors like squirrel-cage induction motors, where speed can vary. Below are the key features and types of synchronous motors.

Speed Determination:

- The speed of a synchronous motor is precisely determined by the number of pairs of poles in the motor’s construction. This speed is always a multiple of the line frequency of the AC power supply. This synchronous speed characteristic makes them suitable for applications requiring precise speed control.

Size Range:

- Synchronous motors are available in a wide range of sizes. They vary from small self-excited units used for powering clocks to large DC-excited units with integral-horsepower ratings commonly employed in industrial settings. The selection of motor size is determined by the particular power and performance needs of the application in question.

Efficiency Advantages:

- Synchronous motors with integral-horsepower ratings tend to be more efficient compared to induction motors with equivalent horsepower and speed specifications. This enhanced efficiency can result in energy conservation, particularly in industrial environments and applications where high efficiency is essential.

Power Factor Control:

- Synchronous motors have a significant advantage in power factor control. When operated at their normal field current, they provide a unity power factor and minimum stator current. By adjusting the field excitation, the power factor can be varied from a low lagging to a low leading condition. This feature offers a convenient method for correcting power factor in electrical systems, which is important for maintaining system efficiency.

Types of Synchronous Motors:

- Non Excited Synchronous Motors:

- These motors come in reluctance and hysteresis designs.

- They have self-starting circuits and do not require external excitation to initiate motion.

- Suitable for applications where ease of starting is essential.

This type of synchronous motor is divided into the following categories, each of which has unique features:

- Hysteresis Motors

- Reluctance Motors

- Permanent Magnet Motors

- Shaded Pole

2. DC-Excited Synchronous Motors:

- DC-excited synchronous motors are typically manufactured in integral-horsepower sizes.

- They require a direct current (DC) supply, either through slip rings from an external source or a DC generator connected directly to their shafts.

- DC excitation allows precise control over motor performance and speed.

Operation at Synchronous Speed:

- The key to synchronous motor operation is achieving and maintaining synchronous speed. Initially, the motor rotor is brought up to synchronous speed through one of two methods.

- Once the rotor reaches synchronous speed, its poles are attracted by the rotating stator’s magnetic field, locking the rotor into step magnetically with the field.

- Importantly, synchronous motors develop torque and operate efficiently only when running at synchronous speed. If the rotor deviates from this speed for any reason, the motor will lose attraction, torque production ceases, and the motor stops.

In summary, synchronous motors are characterized by their constant-speed operation synchronized with the AC line frequency. They offer efficiency advantages, precise speed control, and the ability to control power factor. There are two major types: non excited and DC-excited synchronous motors, each with specific applications and starting methods. Maintaining synchronous speed is crucial for these motors to operate effectively and develop torque.

AC Motor Applications

Poly-phase or Asynchronous Motors Applications

- Petroleum and Chemical pumps

- Cooling Towers

- Air-handling equipment

- Compressors

- Process machinery

- Blowers and Fans

- Drilling Machines

- Grinders

- Lathes

- Conveyors

- Crushers

Synchronous Motors Applications

- Power Generation

- Wind Energy turbines

- Power Factor correction

- Voltage Regulation of Transmission lines

- Electric clock drives

- Servo drives

- Compressors, etc

Advantages of AC motors

AC (alternating current) motors offer several advantages, which contribute to their widespread use in various applications. Here are some of the key advantages of AC motors:

- Ease of Use: AC motors are relatively straightforward to operate and control. They don’t require complex starting equipment in most cases, making them user-friendly.

- Wide Voltage Range: AC motors can operate over a wide range of voltages, making them versatile and adaptable to different power supply conditions.

- Low Maintenance: AC motors, particularly induction motors, are known for their low maintenance requirements. They have fewer moving parts compared to some other types of motors, reducing the need for frequent servicing.

- High Efficiency: AC motors, especially three-phase induction motors, are highly efficient, leading to energy savings and reduced operating costs.

- Variable Speed Control: With the use of variable frequency drives (VFDs), AC motors can offer precise control over speed and torque, allowing them to adapt to various load conditions and improve efficiency.

- Smooth Operation: AC motors typically provide smooth and continuous operation, making them suitable for applications where smooth motion or rotation is required, such as fans and conveyors.

- Durability: AC motors, especially squirrel-cage induction motors, are robust and can withstand harsh operating conditions, including high temperatures and dusty environments.

- Cost-Effective: AC motors are generally cost-effective in terms of both initial purchase price and long-term operating costs due to their efficiency and durability.

- Versatility: AC motors are available in a wide range of sizes, types, and configurations, making them suitable for diverse applications across various industries, from household appliances to heavy industrial machinery.

- Regeneration Capability: Some AC motor types, such as synchronous motors, can operate as generators during braking, converting excess energy back into the electrical system, which is advantageous for energy recovery and control.

Disadvantages of AC motors

While AC motors offer numerous advantages, they also come with certain disadvantages and limitations that are important to consider for specific applications. Here are some common disadvantages of AC motors:

- Limited Speed Control: Standard AC induction motors have limited speed control capabilities without the use of additional devices like variable frequency drives (VFDs). They are typically designed to run at a constant speed determined by the supply frequency.

- Lower Starting Torque: AC induction motors, especially single-phase types, may have lower starting torque compared to other motor types like DC motors. This can limit their ability to start and accelerate heavy loads.

- Complex Control with VFDs: To achieve variable speed control with AC motors, you often need to use variable frequency drives (VFDs), which can add complexity and cost to the system.

- Reduced Efficiency at Low Speed: AC motors, particularly induction motors, may experience reduced efficiency at low speeds, which can be a concern when precise control at slow speeds is required.

- Inrush Current: When AC motors start, they can draw a high inrush current, which may cause voltage drops and affect other equipment connected to the same power supply.

- Power Factor Concerns: AC motors, if not properly controlled, can have a power factor that lags or leads the ideal value, which may require power factor correction measures.

- Complex Control Systems for Synchronous Motors: Synchronous motors, while offering precise speed control, require more complex control systems and often external DC excitation sources, adding to system complexity and cost.

- Cost of VFDs: The cost of VFDs required for variable speed control can be significant, especially for larger motors.

- Noise and Vibration: AC motors can generate noise and vibration during operation, which may be a concern in applications where quiet and smooth operation is required.

- Harmonics and Electromagnetic Interference: VFDs used with AC motors can introduce harmonics and electromagnetic interference (EMI) into the electrical system, requiring additional filtering and mitigation measures.

Also Read: Electrical Transformers | A Deep Dive into its Mechanics

Frequently Asked Questions (FAQs)

What is the main advantage of AC motors over DC motors?

AC motors are preferred for their ability to start and stop smoothly, making them suitable for a wide range of applications. They are also more efficient in converting electrical energy into mechanical work compared to DC motors.

Can AC motors be used in household appliances?

Yes, AC motors are commonly used in household appliances such as refrigerators, washing machines, and ceiling fans due to their reliability and efficiency.

What are some maintenance tips for AC motors?

Regular maintenance includes lubrication of moving parts, checking electrical connections, and keeping the motor clean. It’s essential to follow the manufacturer’s guidelines for specific maintenance requirements.

Are there energy-saving variants of AC motors?

Yes, energy-efficient AC motors are available that meet or exceed specific efficiency standards. These motors help reduce energy consumption and operating costs.

What is synchronous speed?

Synchronous speed is the constant rotational speed at which the magnetic field produced by the AC power source in an electric motor matches the rotor’s speed, resulting in no slip between the two.

How can you differentiate an AC motor from a DC motor?

You can differentiate an AC motor from a DC motor by the type of power they use. AC motors run on alternating current, while DC motors run on direct current. Additionally, AC motors typically don’t require brushes and commutators, while DC motors often do.